Events

Innovating in Engine Cylinder Block Molds

News 2025-04-06 36

Engine cylinder block moldings play a crucial part in the automotive sector, ensuring the accuracy and excellence of engine components. Well, we're sort of the big shots at making these molds and we're famous for our fancy abilities and the way we push boundaries to excel.

Advanced Manufacturing Techniques

Customization and Collaboration

Quality Control and Standards

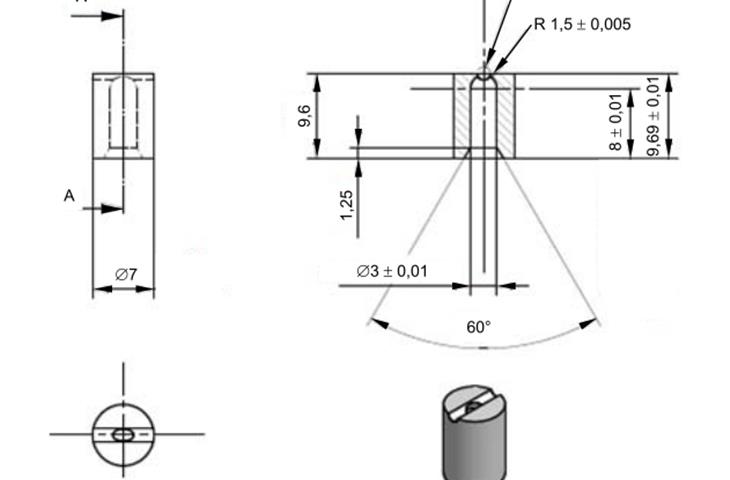

In the engine cylinder block molds factory, quality control is paramount. We follow strict international guidelines so every single mold we make ticks all the quality criteria.

We subjected these molds to numerous tests and inspections throughout the manufacturing process. Quality pays off as people and accolades appreciate our products.

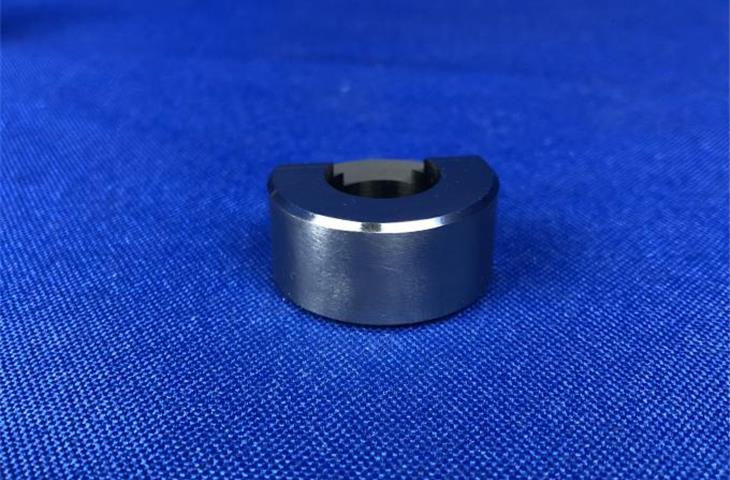

On one occasion, a major automotive firm approached us to create molds for a new car model. The tight deadlines and complex design requirements were challenging, but Our team's commitment and expertise guaranteed that the molds were delivered promptly and at the highest quality. The client was extremely satisfied with the molds, and it was rewarding to see that our efforts had paid off.

Advanced Manufacturing Techniques

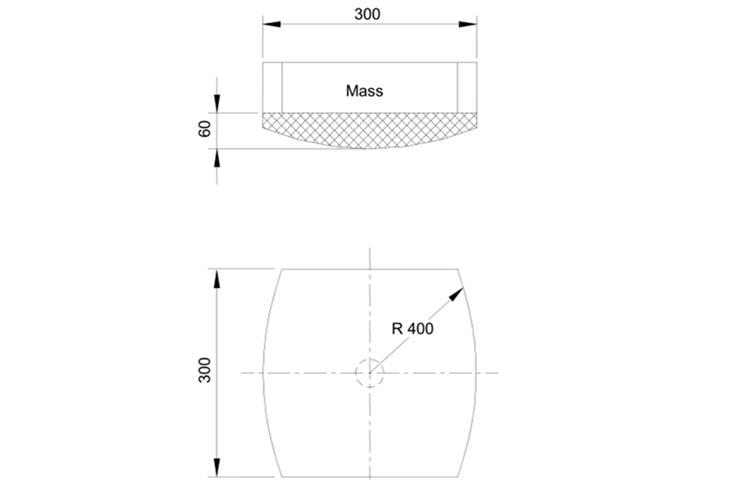

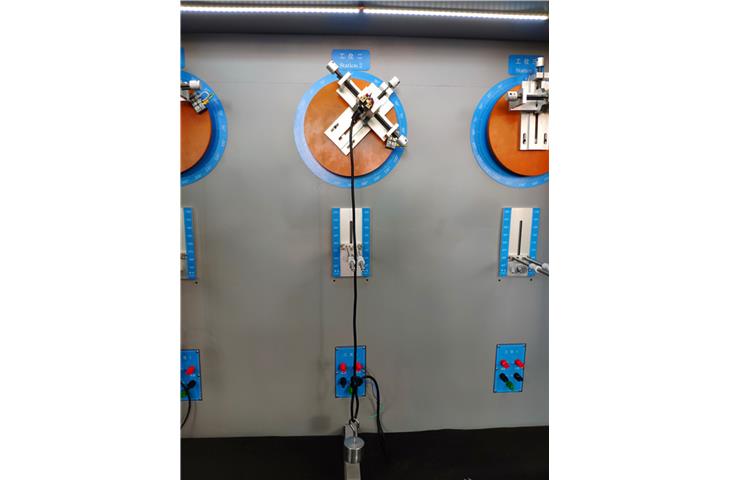

We are utilizing the most up-to-date and advanced tools to fabricate these engine cylinder block molds. We are employing truly cutting-edge equipment such as CNC machines, 3D printers, and various impressive gadgets to produce these molds with exceptional precision and remarkable efficiency. This enables us to create intricate designs effortlessly and provide them to our clients within a timely fashion.

Like lately, we made this Very detailed Shaping device for a Motor block. With our Advanced 3D printing, we Printed the Shaping device that fit All the specific details like a glove and also Reduced on the The duration for creation to Design and produce it. That helped our client save Significant savings and also made the Motor way Enhanced performance.

Customization and Collaboration

We know that every client we deal with has their own Unique requirements. So, we give each Shaping device a Individual customization that fits just right.

We Engage in discussions and listen to our clients real close to know what they need. Then we Design and produce the Shaping devices just how they want 'em. Our way of Cooperation with clients has turned a lot of one-off dealings into Lasting associations.

One notable collaboration was with a Exacting car manufacturer that needed a specialized Shaping device for a Stressed zone of their Motor. We did A LOT of In-depth investigation, and we came up with this Shaping device that not only Fully addressed requirements but also upgraded the Motor's Vital performance. It was Success, and that project made for a Excellent collaboration with the company.

Training and Development

It's all about maintaining our workforce on top of their game. We keep our keeping training current so our employees are aware of all the newest methods. It all supports us in maintaining our leading position when it comes to manufacturing engine cylinder block molds.

We recently hosted a training session on those cutting-edge CNC machining methods. It was a senior expert leading the training and transmitting his expertise. The outcome of the training was that our engineers gained extremely valuable knowledge they can apply daily to enhance our mold quality.

Related articles

- Why Choose the Right Drop Test Steel Ball Supplier?

- China Plastic Gauge: A Comprehensive Overview

- Choosing the Right Test Equipment Supplier When

- Why ISO Luer Standards Are Essential in Medical Devices

- The Essential Aspects of Quality IEC Test Equipment

- Why Choose Local Used Test Equipment Distributors Near Me?

- Why Other Rehabilitation Testing Equipment Matters

- Ect Sample Cutter Supplier: Plans for Precision Cutting