Products

Intelligent Water Supply Control Cabinet IPX3/4 Oscillating Tubes Test Equipment IEC 60529-2013

Products Description

Intelligent Water Supply & Control Cabinet IPX3/4 Oscillating Tubes Test Equipment IEC 60529-2013

Product Information For IPX3/4 Oscillating Tube Testing Equipment:

IPX3~4 oscillating tubes test system is designed and manufactured according to IEC60529:2013. It is used for testing the IPX3/IPX4 waterproof level of electrical and electronic products.

The complete set of IPX3~4 oscillating tubes test system is composed of one set of oscillating tube swing device, oscillating tubes of R600mm and R1000 mm, a turntable, and an intelligent water supply and control cabinet.

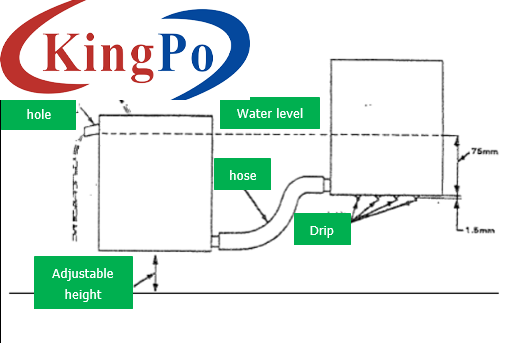

The intelligent water supply and control cabinet is composed of a water supply tank, a water pump, and a control system. The test water supply flow is controlled by a PLC, a frequency converter, and a flow meter.

The IPX3-4 Oscillating Tubes Test System is a specific type of test equipment used to evaluate the water resistance or ingress protection (IP) rating of electronic devices, enclosures, and other products. The IPX3-4 rating specifically pertains to the resistance against water spray and splashing.

This test system consists of oscillating tubes that generate controlled water sprays at varying angles and intensities. It is designed to simulate specific environmental conditions, such as rain or water splashing, to assess the product's ability to withstand moisture penetration.

In an IPX3 test, the system produces a spraying water stream at an angle of 60 degrees from the vertical direction onto the sample. This simulates water spray coming from a rainfall source. The water flow rate is typically set at 0.7 liters per minute, and the test duration is usually five minutes.

For an IPX4 test, the spraying water stream is increased in intensity. The sample is subjected to water sprayed from all directions, including from above and the sides. The flow rate is typically increased to 10 liters per minute, and the test duration remains at five minutes.

During the test, the sample is placed inside a controlled enclosure to prevent water from damaging any sensitive components or mechanisms. After the test, the product is inspected for any signs of water ingress, such as moisture, droplets, or damage to internal components.

The IPX3-4 Oscillating Tubes Test System is widely used in industries such as electronics, automotive, lighting, and outdoor equipment manufacturing. It helps ensure that products meet the required IP rating standards for water resistance and can withstand various levels of exposure to water spray and splashing.

Technical Parameters For IPX3/4 Oscillating Tube Testing Equipment:

Water flow rate>10L/min±5% clean water without inclusion.

This device is equipped with clean water filtration unit

Max. ±175° can be preset

(Note: standard requires IPX3:120°; IPX4:360°, but due to there is turntable under oscillating tube during test, so 360° can not achieved during actual testing, if without turntable, then 360° can be achieved)

IPX3:4s/time (2×120°);

IPX4:12s/time (2×360°);

Can be set according to the size of the oscillating and the number of the pin holes (0.07 L/minX per hole)

The ground should be flat, with good function of inflow and drainage.

The wall of the testing area should be waterproofing.

10A waterproof leakage switch (or socket) used for equipment.

0.6Mpa~0.8Mpa Compressed air is required, should be prepared by user

No.

Item

Parameters

1

Water supply

2

The size of the oscillating tube

Coming with R600mm, R1000mm oscillating tube, made of stainless steel

3

Needle hole

Inside diameter: Φ0.4mm, distance between each two neighbor holes is 50mm

4

Included angle of two holes

IPX3:120°; IPX4:180°

5

Oscillating tube swing angle

6

Raining speed

7

Water flow

8

Testing time

1-99999S can be preset

9

Pressure gauge

0~0.25MPa

10

Turntable

Diameter: Φ600mm, rotation speed: 1r/min, bearing capacity: ≤50kgs

11

Site requirements

12

Electrical control

PLC & touch screen

13

Power supply for this equipment

AC 230V±10%, 50Hz, 2KW

14

Power supply for sample

AC230V±10%, 10A