Products

IPX3/4/5/6 Spray Nozzle And Hose Nozzle Test System With Water Supply Tank IEC 60529

Products Description

IPX3/4/5/6 Spray Nozzle And Hose Nozzle Test System With Water Supply Tank IEC 60529

Product Information For IPX3/4/5/6 Spray Nozzle And Hose Nozzle Test System:

Standard: IEC 60529-2013 “Degrees of protection provided by enclosure (IP code)” IPX3, IPX4, IPX5 and IPX6.

The testing system is used to verify the protective performance of the enclosure for electronic and electrical products, automobiles, motorcycle parts, household appliances, seals and lamps under water jets at degree IPX3, IPX4, IPX5 and IPX6.

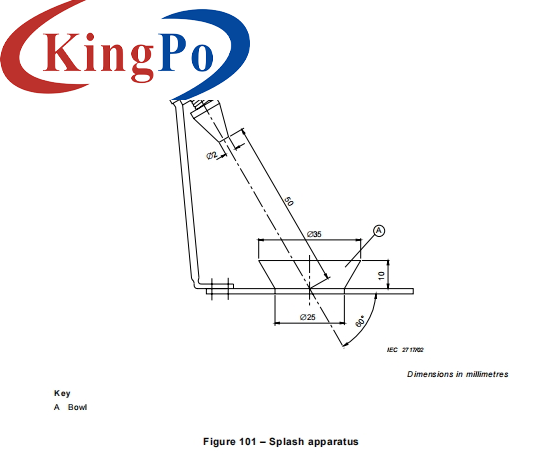

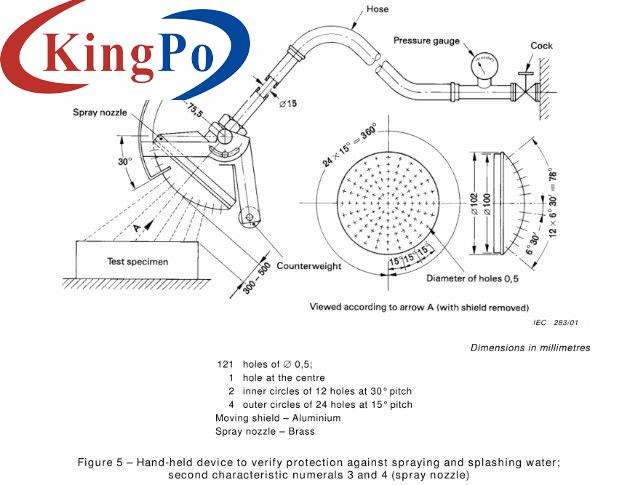

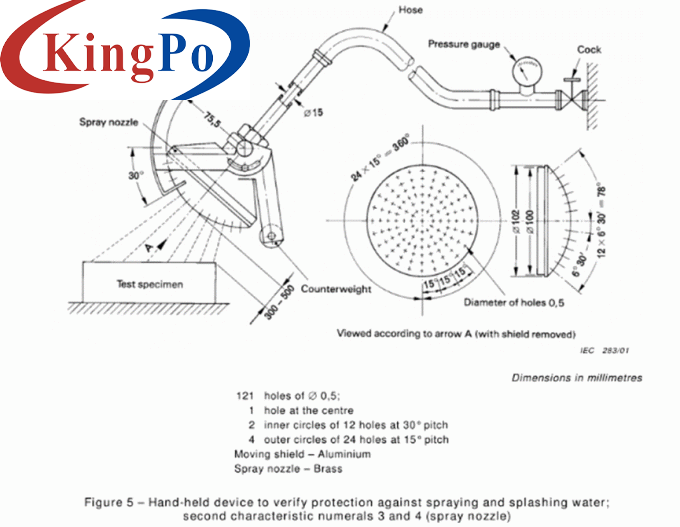

This IPX4, IPX5 and IPX6 water ingress testing equipment ensures that the water spray speed reaches the standard required value by controlling the water supply flow, the enclosure is sprayed from all practicable directions with a stream of water from the standard test nozzles as shown in IEC 60529 figure 5 and 6.

Structure For IPX3/4/5/6 Spray Nozzle And Hose Nozzle Test System:

The whole test equipment consists of one set of IPX3, IPX4 spray nozzle, one set of water jet nozzles, an electrical control cabinet integrated with the water storage tank, a support for nozzles, and a turntable. The sample is placed on the turntable, the turntable is caused to rotating by motor driving at a rotation speed of 1r/min, to make the enclosure is sprayed from all practicable directions with a stream of water from the standard test nozzle. The electrical control part and water storage tank are integrated. This whole system adopts open structure.

Technical parameters For IPX3/4/5/6 Spray Nozzle And Hose Nozzle Test System:

Outer diameter: Ф102mm, spherical diameter: SФ75.5mm, 1 hole at the center, 2 inner circles of 12 holes at 30° pitch,4 outer circles of 24 holes at 15° pitch , total 121 holes of Ф0.5mm, made of brass.

IPX5: Ф6.3mm; IPX6: Ф12.5mm

IPX5: 12.5±0.625L/min

IPX6: 100±5 L/min

IPX3/4

Parameters of Spray Nozzle

Water Flow

10L/min±5%, flow meter is adjustable through rotameter, electronic flowmeter is optional

Pressure

50~150Kpa, the pressure gauge measuring range: 0~0.25Mpa

Moving Shield

Made of aluminum, can be detachable

Water Spray Directions

The angle of water spraying can be adjusted

IPX5/6

Parameters of Hose Nozzle

Delivery Rate

Distance from Nozzle to Enclosure Surface

2.8m ((The distance from the nozzle to the center surface of the turntable, standard requires 2.5-3m)

Water Jet Directions

The angle of water jetting can be adjusted

General

Control & Operation

PLC and touch screen intelligent control system

Nozzle Fixed Method

Spray nozzle and hose nozzles are fixed on the support

Pressure Gauge

0~0.25MPa, can be displayed

Test Duration

0.01S~99.9 min, can be preset

Turntable

Diameter: Φ600mm, rotation speed: 1r/min, bearing capacity: ≤50kgs

Water Storage Tank

This test system adopts open type structure, the test water is not recycled. The test system is equipped with an approximately 500L stainless steel water storage tank. The water storage tank is equipped with a water level float valve to automatically control the water inlet, and has high and low water level alarm detection, to effectively prevent the pump from being damaged due to dry water. The water storage tank and electrical control part are integrated.

Safety Protection

Phase sequence protection, leakage protection, water shortage protection, abnormal protection.

Power Supply

AC380V,50Hz, 4KW