Products

IPX6K9K Water Ingress Testing Equipment High Temperature Water Spray Stainless Steel Chamber

Products Description

IPX6K9K High Temperature Line Speed Rain Water Spray Testing Equipment

Overview:

The test chamber is made of high-quality materials and processed by the most advanced processing equipment in the China. The surface of the outer chamber is spray-coated, beautiful and smooth. The color is coordinated, and the lines are smooth and natural. The inner is made of international high quality stainless steel. The indoor sample holder and other accessories are made of stainless steel or copper. The design is reasonable and durable. Under the premise of complying with standards, the equipment is more practical and easy to control based on the stability of all aspects.

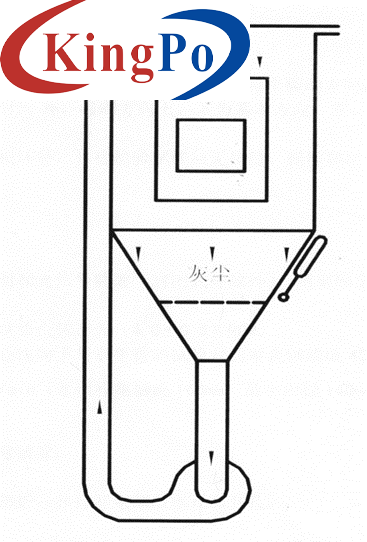

The whole chamber of the waterproof test equipment adopts the whole structure and is divided into three parts: upper, lower and right. The upper part is the working chamber, the lower part is the mechanical room, and the right side is the electrical control cabinet.

It is used to inspect the IEC enclosures for the electrical equipment (IP supplementary code test), in accordance with the relevant specifications in the DIN40050 standard. Mainly for the provision of automotive parts, motor and electronics industry, simulation of natural environment or human factors designed waterproof test machine.

This equipment is designed and manufactured according to Clause 14.2.9 of IEC 60529:1992+A2:2013, ISO 20653-2006, QC/T 413-2002, DIN40050-9.

Technical Parameters:

0°, 30°, 60°, 90°, average distribution vertical direction

The grounding resistance of the protective ground wire is less than 4Ω;

The user is required to configure the device with a corresponding capacity of air or power switch at the installation site, and this switch must be used exclusively for this device.

Dimensions

Inner size

1500 x1500 x1500mm (can be customized)

Outer size

2000x3800x2450mm (D*W*H)

IP9K

Water temperature

80±5°C (hot water injection test, high pressure thermal spray)

Rotary table

Diameter:Φ800mm. Load bearing≤50kg (can be customized)

Location of nozzles

Number of nozzles

4

Water flow

14-16L/min

Spray pressure

8000~10000Kpa

Distance from nozzle to sample

100-150mm

Rotary table rotation speed

5±1r.p.m

Connecting pipe

High pressure stainless steel hydraulic pipe

Solenoid valve

Italian high temperature and high pressure solenoid valve

Water pump

Italian high temperature and high pressure water pump

Heater wire

6KW Germany heater wire

Test time

0-99h 59min

Controller

Germany Siemens + Siemens touch screen (other brands optional)

Spray system

4 nozzles, Install 1 nozzle every 30 °C

Outer chamber

SUS202# stainless steel plate or cold-rolled plate spray

Inner chamber

SUS304# stainless steel material

IP6K

The nozzle diameter

Ф6.3mm

Water pressure

1000kpa (Adjusted by flow)

Water flow

75±5 L/min (High voltage electronic flowmeter high pressure and high temperature)

Test time

3,10,30,9999 min, adjustable

Run time control

1-9999 min, adjustable

Spray pipe

High pressure resistant hydraulic pipe

High pressure solenoid valve

International high pressure solenoid valve

High pressure water pipe

Hydraulic high pressure hydraulic pipe

Voltage regulator

Taiwan Delta

Use Environment

Temperature

RT+10℃~+40℃

Humidity

≤85%

Power

AC380( ±10%)V, 50Hz, (customizable), Three-phase five-wire

Power supply capacity

Protector

Leakage protection, short circuit protection, water shortage, motor overheating protection