Products

ISO 6941 Textile Damaged Length And Flammability Time Vertically Test Chamber

Products Description

ISO 6941 Textile Damaged Length And Flammability Time Vertically Test Chamber

Product Information:

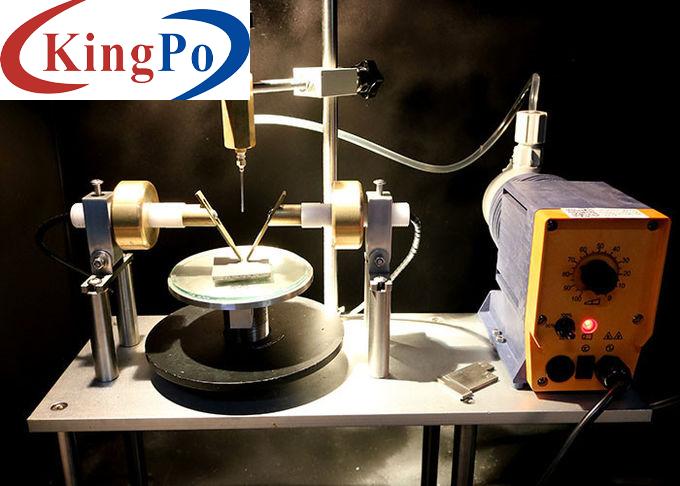

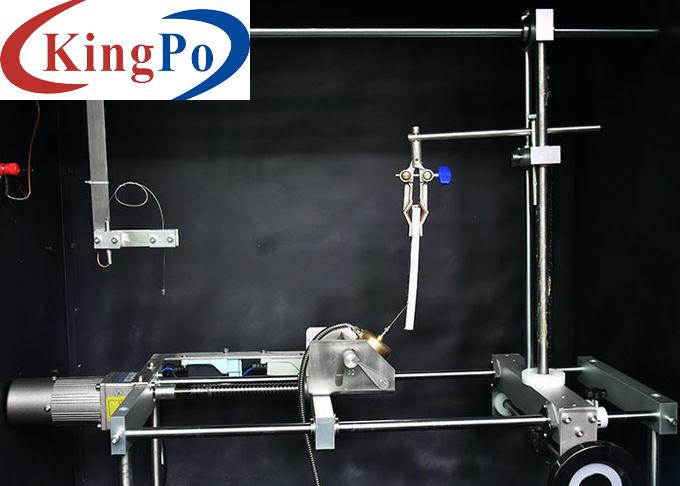

The test chamber is designed and manufactured according to the standard requirement of ISO 6941.

It is suitable for the vertical combustion performance test of textile fabrics and industrial products of all kinds of single or multi-component (coating, quilting, multi-layer, sandwich products and similar combinations).

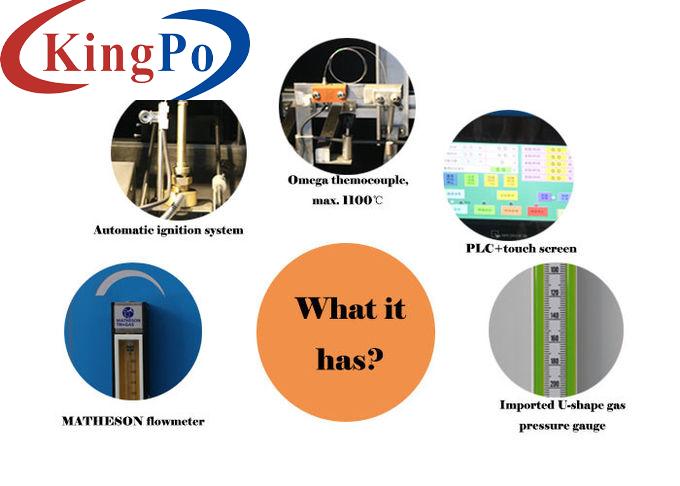

This equipment adopts high-precision instruments, automatic ignition system, precision flow regulator, so it has the advantages of simple-accurate flame adjustment, stable performance and convenient operation.

Test principle: It is used a regulated igniter to ignite, and simulate the flame to ignite the bottom edge of the sample in the vertical direction. After the regulated time, measure the afterburning, smoldering time and damage length of the sample to judge whether the sample is qualified or not.

Technical Parameters:

A: Select propane or butane or a mixture of propane butane;

B: Select methane with a purity higher than 97%

Power supply: single-phase AC22V±10%, 50/60Hz

Ambient temperature: 10℃~35℃ Relative humidity: 30%~90%

Applied standard

ISO 6941

Working power

220V/AC50HZ 3A

Control method

Key operation, optional PLC control + touch screen operation

Chronograph

9999X0.01s

Burning angle

25°, adjustable

Test clip

It is made of two U-shaped stainless-steel plates of 422*89*2mm, and the inner frame size is 356×51mm

The height between the bottom and the nozzle of the igniter

17mm

Specimen frame

560×170mm, 12 specimen fixing pins and 8 positioning cylinders are arranged

Flame height

Adjustable, regulated by flow meter

Gas category

Hammer

54.5, 113.4, 226.8, 340.2, 453.6g, (including a diameter of 1.1, a length of about 76mm, and a 13mm end bent at a 45° angle)

Absorbent cotton

Equipped with 2 packs of medical absorbent cotton

Illumination

Equipped with test chamber lighting with control

Dimensions

WDH=1200×700×1200mm,130kg

Use environment

Combustion chamber

Made of stainless steel, with a heat-resistant transparent observation window; chamber size:329±2* 329±2* 767±2 mm(W*D*H); the bottom plate of the chamber is 304×304×3mm; the receiving tray is 152× 152×1.5mm; there are brackets and test clip fixing devices on the top and side of the chamber to fix the test clips. There are 16 exhaust holes with an inner diameter of 12.5mm on the top of the chamber, and a top plate is installed 30mm away from the top of the chamber to prevent the airflow outside the box. There are 6 ventilation holes with an inner diameter of 12.5mm on both sides of the box, and ventilation holes are arranged around and at the bottom, W×D×H=385mm×204mm×360mm