Products

ISO3795-1989 Flammability Test Chamber for Automobiles Interior Materials

Products Description

ISO3795-1989 Flammability Test Chamber for Automobiles Interior Materials

Product overview:

The device uses an integral intake automatic ignition system with a combustion delay of only 0.1 seconds to ensure full combustion of the gas. It is applicable to the evaluation of horizontal combustion characteristics of interior materials for automobiles (cars, multi-purpose passenger vehicles, trucks, buses).

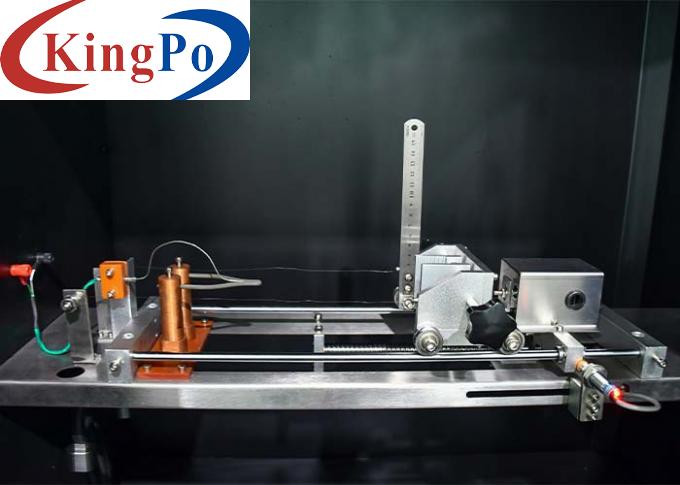

The testing machine consists of control box, combustion box, burner, electromagnetically operated valve (flowmeter), high voltage igniter, thermometer, signal control line, sample bracket, fume hood, etc. Control box and combustion box are made of stainless steel, beautiful appearance, smoke, gas corrosion, high degree of automation control system, with automatic ignition, automatic air supply, automatic timing, automatic end of the test and other functions.

Use environment:

Power supply: single-phase AC220V± 10%, 50/60Hz

Technical parameters:

System Composition

Control devices, combustion chamber, burner, flow meter, specimen fixture, air pipe and fume hood

Control Devices

The control part is installed on the left side of the combustion chamber, which integrates timing, flow regulation, lighting, and fan on the control panel.

Flame Application Timer

0~999.9/S/M/H, can be preset, accuracy ≤0.5s

Burning Timer

0~999.9/S/M/H, accuracy ≤0.5s

Flame Height

38mm, observed through a 38mm flame height gauge, adjustable by flow meter

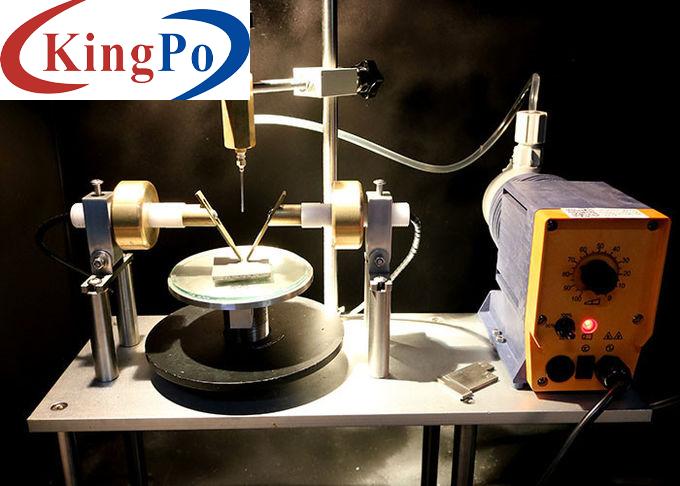

Burner

Inside diameter 9.5 mm. It is located in the test cabinet so that its nozzle center is 19 mm below the center of the bottom edge of the sample opening end. It is made of brass and has an automatic ignition function.

Specimen Holder

U-shaped bracket: It is made of two U-shaped corrosion-resistant metal plates, there are 6 pin holes on the upper bracket and 6 pin holes on the lower bracket, and the support form is that the heat-resistant steel wire with a diameter of 0.25 mm spans the frame at an interval of 25 mm on the lower U-shaped frame. The lower plane of the sample should be 178 mm above the floor. The front end of the sample holder is 22 mm away from the end of the box, and the longitudinal side of the sample holder is 50 mm away from the side of the box.

Test Gas

The gas supplied to the burner shall have a calorific value of approximately 38MJ/m³, such as natural gas, city gas, liquefied gas

Metal Comb

At least 110mm in length, with seven to eight smooth rounded teeth per 25mm

Combustion Chamber

Length: 385 mm, depth: 204 mm, height: 360 mm. There are ten exhaust holes with a diameter of 19 mm at the bottom of the burning chamber. The four side walls have 13 mm wide ventilation slots near the top. The top part of the combustion chamber is provided with a hole for inserting a thermometer. The hole is arranged at the center position of the top, and the center of the hole is 20 mm from the inside of the rear panel. A collecting tray for collecting molten droplets is arranged at the bottom of the combustion chamber, and the tray is arranged between two rows of air vents without affecting the ventilation of the air vents.

It is mainly used as an interior material for automobiles (cars, multi-purpose passenger vehicles, trucks, buses).

Ambient temperature: 10 ° C to 35 ° C Relative humidity: 30% to 90%