Products

Leak Test Fixture For SSPPM Bezel For Test Waterproof Ability Of The Medical SSPPM Shell

Products Description

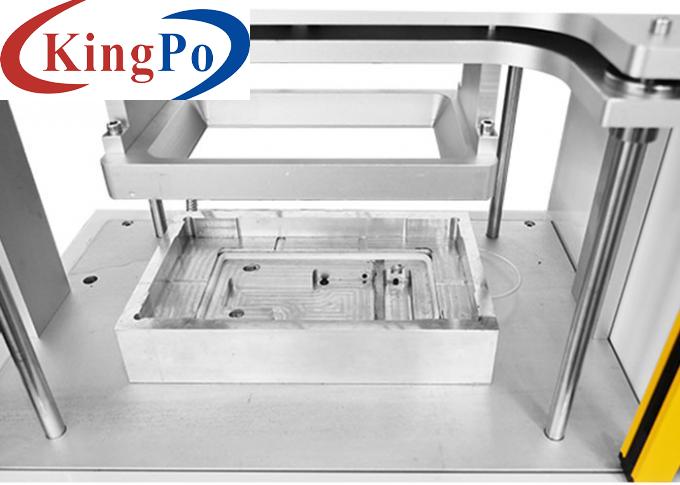

Leak Test Fixture For SSPPM Bezel For Test Waterproof Ability Of The Medical SSPPM Shell

Product Information:

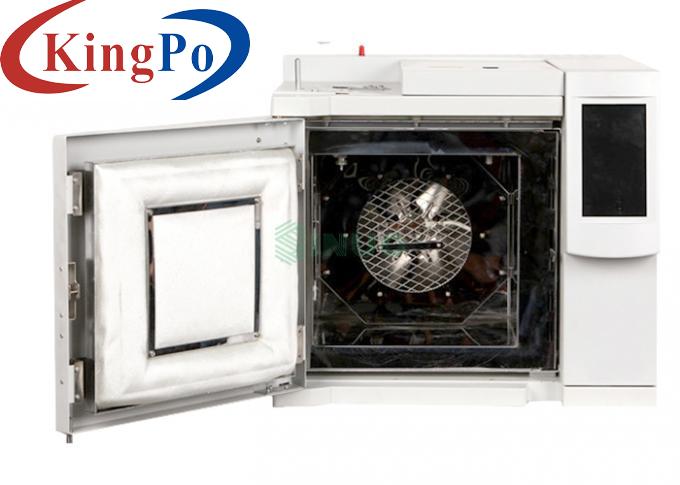

The test device is designed and manufactured strictly according to the customer's customized requirements. It is used for the verification of the waterproof ability of the medical SSPPM shell. It is a special test equipment and is suitable for testing and certification agencies and factory laboratory testing departments.

Equipment principle: Use the cylinder to drive the down-pressing fixture, and tightly compress the frame around the sample, so that the down-pressing fixture and the upper surface of the sample form a water storage tank. At the same time, due to the effect of two layers of sealing rubber pads, the lower surface of the sample and the lower groove of the compartment form a sealed air-filled compartment, which are divided into two inflatable compartments, one is the LCD sealed compartment area (LCD compartment), and the other is the keypad sealed compartment area (keypad compartment).

The system controls to fill the water storage tank with water, and then automatically inflate the LCD compartment to the set pressure (monitored by the pressure sensor), and set the time at constant pressure, and observe whether there are bubbles around the LCD upper surface of the sample in the water storage tank. Then deflate the LCD compartment, re-inflate the keypad compartment, observe whether there are bubbles in the sample keypad compartment area in the water storage tank, and accurately judge the leak point.

Technical Parameters:

1 Routine maintenance: disconnect the power supply when the device is not working, and keep the device clean.

2 Regular maintenance: Regularly lubricate the bearing (lubricant can use PARKER EO-NIROMONT, etc., and perform maintenance every 3-6 months)

3 Calibrate the pressure sensor once a year.

4 Regularly drain the water in the air filter, and regularly add lubricating oil to the lubricant spray bottle (you can add it when the amount of lubricate oil is too low)

Troubleshooting:

1. Blown fuse, bad power connection.

2. The indicator light is damaged.

1. Check the power socket, measure the supply voltage, replace the indicator light.

2. Replace the fuse core.

1. The DC power supply has no 24V voltage.

2. The program is corrupted.

3. The communication cable between HMI and PLC is not connected or damaged.

1. Check DC power.

2. Re-download the touch screen program.

3. Replace the communication line.

No.

Item

Content

1

Input power

AC220V 50HZ, 2kW

2

Control

PLC control, touch screen operation

3

Test station

1 station, can be customized

4

Drive

Cylinder

5

Test pressure

0.01-0.5Mpa, external air source, pressure sensor monitoring and display

6

Pressure hold time

0-999999s, can be set

7

Sample down-pressing fixture

Customized according to the sample, standard 1 set

8

Fixture compartment

Customized according to the sample, standard 1 set

9

Sealing rubber pad

Customized according to the sample, standard 10 pieces (can seal the LCD compartment and keypad compartment)

10

Water injection

Automatic switch valve

Symptoms

Reason

Troubleshooting

The power light is off

Touch screen failure