Events

Mastering Large Capacity High Temperature Test Chamber Operations

News 2025-04-19 10

Since I started working with those large high-temperature test chambers, I've been very interested in how precise and in control they are. They're not only for testing items. They're like a view into seeing how things react when they're extremely hot or under severe stress.

2. Application in Material Testing

3. Environmental Control and Simulation

5. Data Analysis and Reporting

1. Calibration and Accuracy

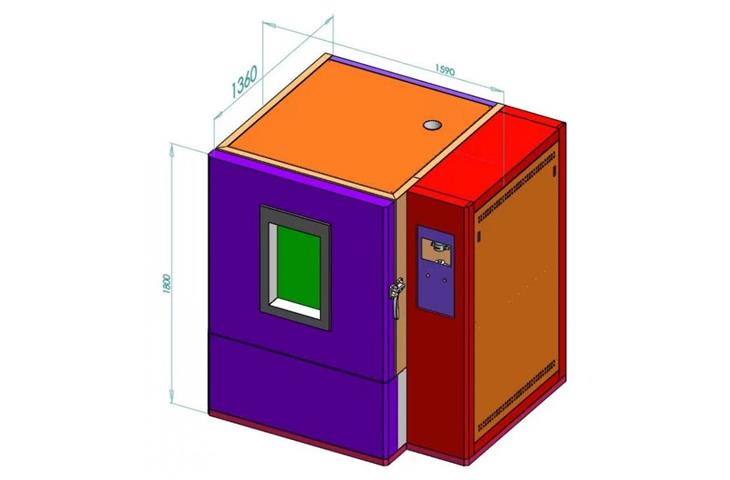

The major concern with these big high temp chambers is ensuring they're calibrated and exceedingly accurate. I remember my first calibration like it was only yesterday. It was a actual fussy procedure.

We had this temperature gauge, and we had to really adjust the enclosure to get it dead on with the standard. It's all about adjusting it just right, and once you get the hang of it, the results are pretty reliable.

2. Application in Material Testing

Big altitude temp enclosures are pretty much the standard choice for product testing. I've run everything from metals to plastics through them.

Putting materials through those extreme temperatures and pressures gives us a pretty sound understanding of how they'll act. For example, I did a test on a new alloy once to see how strong it gets extremely heated. The results were super important for the business to know how the alloy would resist the stress.

3. Environmental Control and Simulation

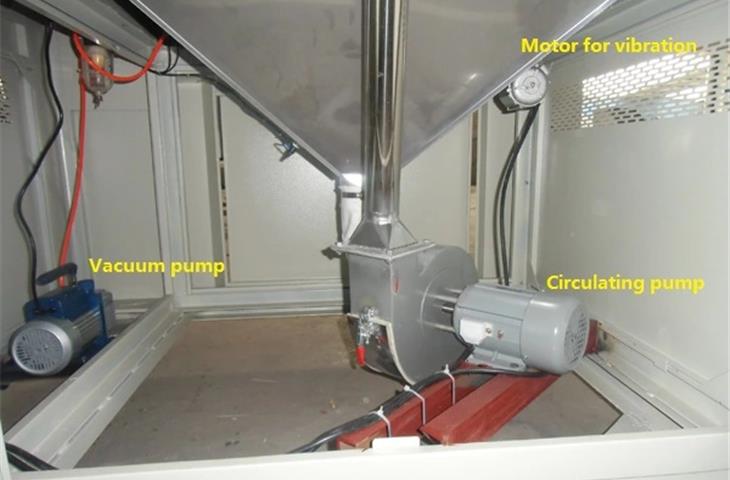

And get this, these test enclosures can simulate all kinds of environments. I've used them to simulate everything from being up altitude to extremely humid.

This is huge in industries such as aerospace and automotive where materials need to withstand in challenging conditions. Having the capability to accomplish all this within a controlled environment is a critical or crucial thing.

4. Maintenance and Safety

You've got to keep those big high-temperature chambers in excellent condition. You need to keep them cleaned, inspect them on a regular basis, and keep them calibrated so they function seamlessly.

And don't forget, safety comes first. I always make sure to follow the manufacturer's instructions and I've always got appropriate safety equipment on. I remember one time when a temp sensor malfunctioned, but thanks to our swift action, nothing bad happened.

5. Data Analysis and Reporting

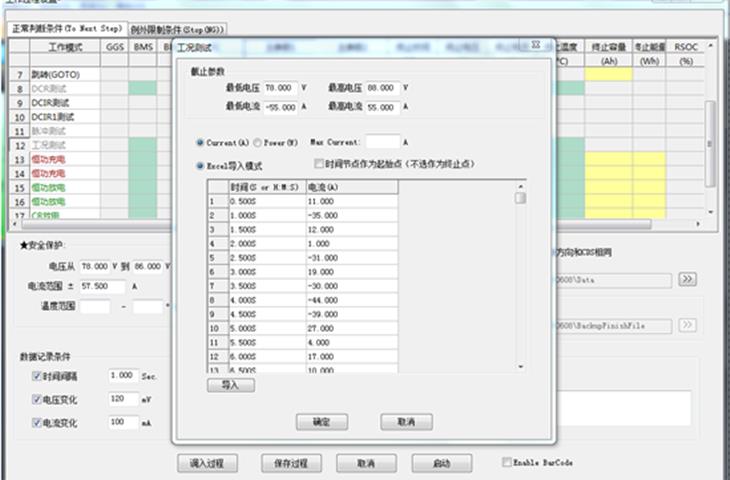

And finally, the data examination and report part is critical. I use different software to look at the data and compile comprehensive reports.

These documents are not solely for us. They're usually intended for clients and all the interested parties. I must ensure These documents are precise and understandable. That is my responsibility.

Related articles

- What is a Cables Heat Aging Test Chamber?

- How Test Equipment Manufacturers Drive Innovation

- Revolutionizing Cooking: Plans for China Hot Air Circulation Oven

- Why UL 1447 Online: Essential Needs and Insights

- The Essential Guide to EMC Test Equipment Where

- Price Precision: Mastering Leather Thickness Measurement

- Why Female Luer Lock Dimensions Matter in Medical Devices

- Finding Test Equipment Electrical Near Me: Your Ultimate Guide