Events

Mastering the Precision of Load Cells Where Innovation Meets Measurement

News 2025-04-18 13

Since I initially learned about load cells in my engineering classes, I've been really into how they convert mass into high precision readings. These little gadgets are extensively used in various industrial applications, from manufacturing products to research equipment. So today, I'm sharing my load cell story, and I'll talk about five key terms that are really important to kCurrently.

Alright, first up: Load Cell Calibration.

Next up, the Load Cell Sensor.

Moving on to Load Cell Application.

Now, let's talk about Load Cell Technology.

Now, let's talk about Load Cell Maintenance.

Alright, first up: Load Cell Calibration.

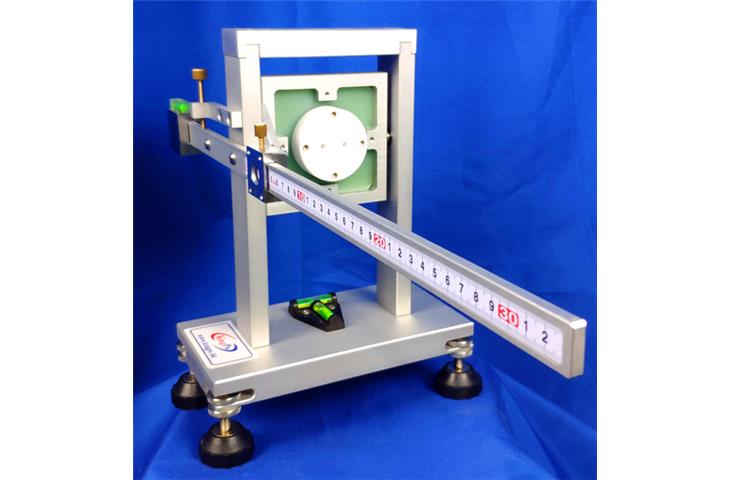

Getting a load cell calibrated is super important for ensuring it's accurate. I remember trying this out in a lab for the first time.

We'd put standard weights on the cell and tweak the circuitry until it aligned with the actual weight. The National Institute of Standards and Technology, or NIST, says that getting the calibration right is a big deal for a bunch of industries, like drugs and planes.

Next up, the Load Cell Sensor.

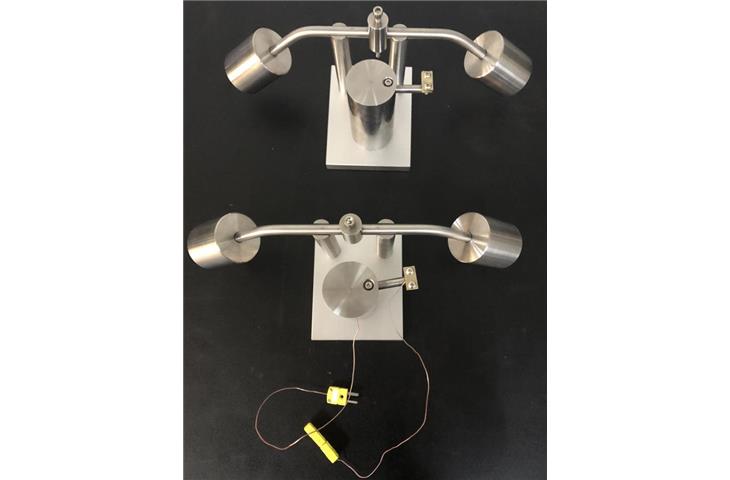

A load cell sensor is like the heart of the system. It converts force into an electrical signal.

I got to mess with strain gauge load cells that use this piezoresistive phenomenon to measure force. These sensors are super sensitive. They can pick up even slight variations in weight. And guess what? A study in the Journal of Materials Science says that strain gauge tech has significantly improved its performance in the last 10 years, increasing the sensors' reliability to an unprecedented level.

Moving on to Load Cell Application.

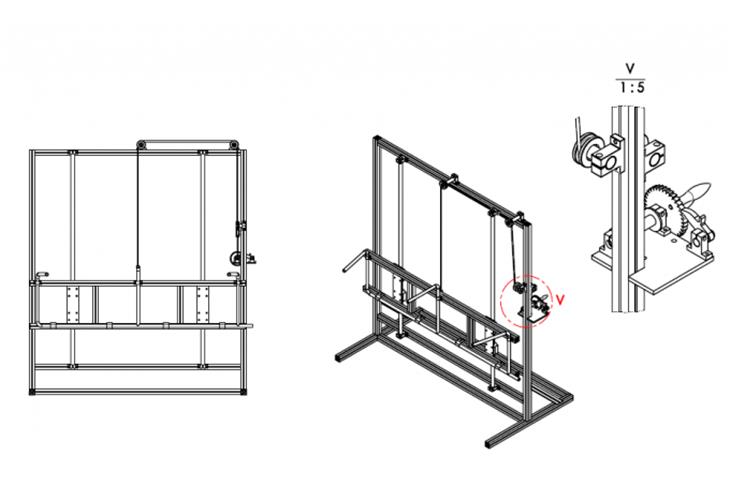

Load cells are really versatile and used in lots of various sectors. When I worked at a manufacturing facility, I saw how load cells are used in packaging equipment to make sure the correct weight.

Also, in building and construction, they use load cells to monitor the weight of materials being lifted by cranes. Load cells are extraordinarily versatile and their applications are expanding with all the technological advancements.

Now, let's talk about Load Cell Technology.

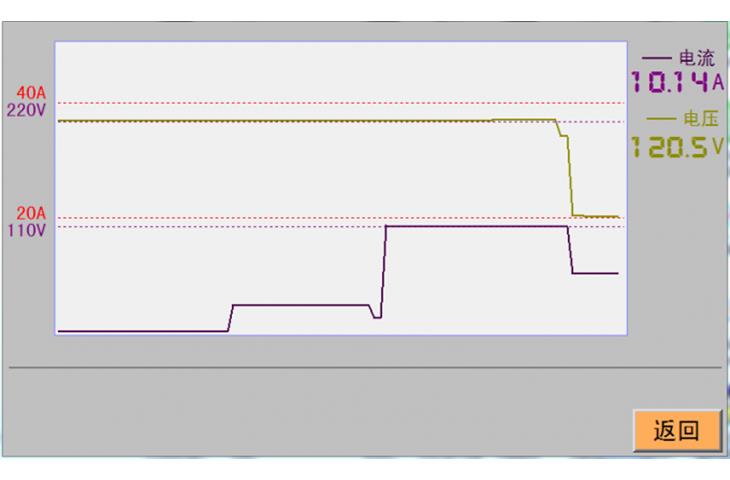

The tech used in load cells has changed a lot over the years. It's gone from basic mechanical load cells to these modern digital versions, and the transformations are significant.

I got to mess with a digital load cell that communicates with a controller over a serial communication, making it possible to monitor things in real time and collect data. MarketsandMarkets says the load cell market is going to grow like rapidly, with a Compound Annual Growth Rate of 4. 2% from from 2021 to 2026, thanks to the rise in the need for precise measurements in various sectors.

Now, let's talk about Load Cell Maintenance.

<p Caring for of your own load cells is extremely crucial for maintaining them working staying powerful as well as precise. During over my professional life, I've observed that consistent cleaning as well as inspection them working out is essential for ensuring from becoming damaged or worn out.

Provided you maintain frequent servicing, your own load cells can continue to give trustworthy readings over a prolonged period. Therefore, while I can't give you specific maintenance tips without chatting with a pro, keep in mind that frequent servicing is extremely crucial for maintaining your own load cells at peak performance.

Related articles

- The Significance of SN4410: A Comprehensive Insight

- Breakdown Voltage Test Machine: Key Aspects and Requirements

- Unveiling the Standards of UL1581 Cables

- Environmental Test Chambers in China: A Comprehensive Guide

- The Essential Aspects of Pressure Testing Equipment

- The IP 5356 Phenomenon: A Closer Look

- What Ventilation Equipment Can Offer: A Comprehensive Guide

- Cycle Thread Bolts Nuts: A Comprehensive Guide