Events

Maximizing Ceramic Strength: A Comprehensive Guide

News 2025-04-14 12

Diving into the realm of ceramic strength testing is like deciphering the mysteries of a robust, resilient material. When you start looking into ceramics, you realize how important knowing their strength is, no matter if it's for aeronautics or construction industry. This article is going to cover five key themes about ceramic strength testing. We'll be using practical experiences, what the specialists assert, and some notable achievement tales.

1. Importance of Ceramic Strength Testing

2. Types of Ceramic Strength Tests

3. Factors Affecting Ceramic Strength

4. Advancements in Ceramic Strength Testing Technology

5. Applications of Ceramic Strength Testing

1. Importance of Ceramic Strength Testing

Ceramic strength testing is more than just knowing how strong the material is. It's about ensuring reliability and safe. For instance, in aerospace, ceramics are used in things like turbo blades and outlets. How strong these materials are can be the distinction of a mission being successful or a big mess. The American Ceramic Society says ceramics can take really high temperatures, up to 3,000 degrees, which is perfect for hot environments.

We achieved a significant success on a project for a top aerospace company. We created a innovative ceramic material that surpassed rigorous strength evaluations, really enhancing the engines' efficiency.

2. Types of Ceramic Strength Tests

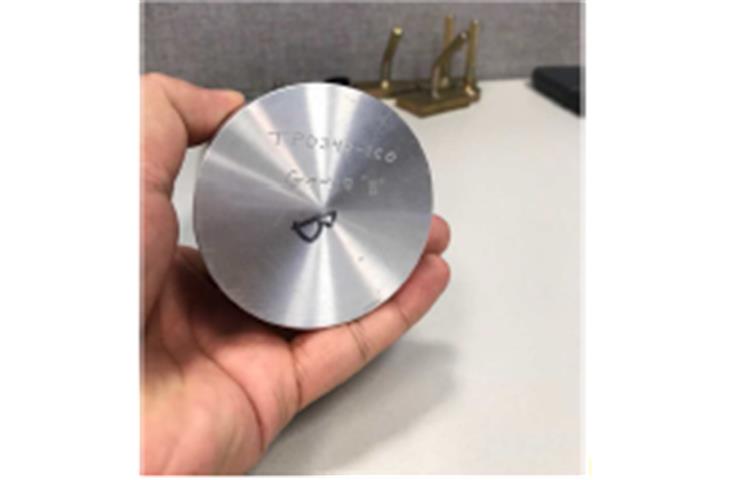

There are numerous methods to test ceramics, each each with its unique procedure. The primary tests are compressive resistance, bending strength, and tensile resistance.

For instance, the compression strength test determines how much pressure a ceramic can withstand before it breaks. It's extremely important for such as hydraulics systems that need strong ceramics.

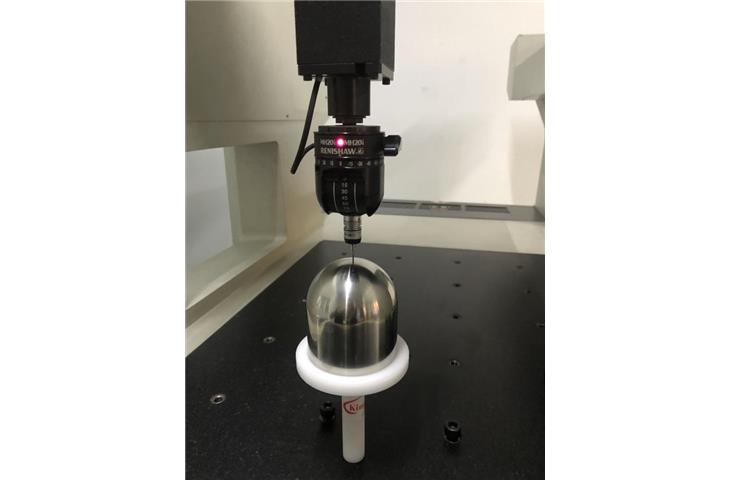

We've got a lot of experience doing These examinations. We built Our self-designed machine to simulate real-world conditions and achieve extremely accurate results. This has helped us spot any defects in ceramics and enhance their quality.

3. Factors Affecting Ceramic Strength

Ceramics can be robust due to various factors: what type it is, how its microscopic structure is arranged, and how it is manufactured. For example, adding certain additives while making ceramics can enhance their strength. And how its small components are assembled can make a major impact in how sturdy and durable they are.

We recently worked on a ceramic that needed a unique design to be sufficiently strong. By thoroughly adjusting the making process, we ensured its functionality just right, showing we possess extensive knowledge of ceramic production.

4. Advancements in Ceramic Strength Testing Technology

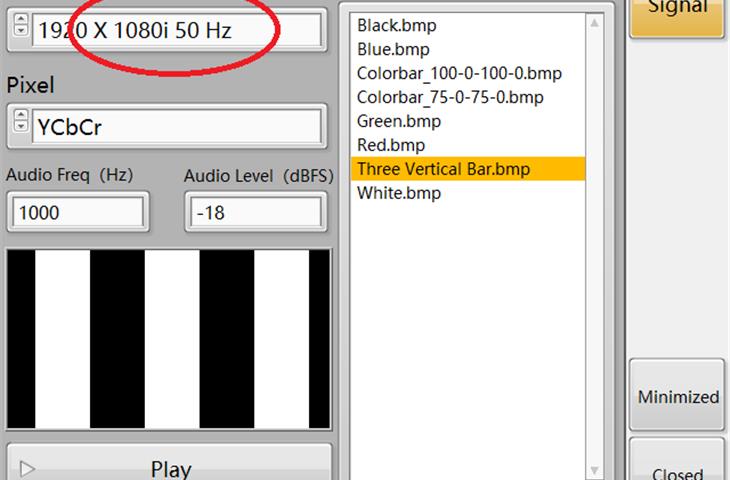

Tech has totally changed how we test ceramics for strength. Things like non-destructive evaluation mean we can check how strong ceramics are without damaging them. It's highly beneficial for stuff that needs to stay strong.

We've been leaders in using these state-of-the-art testing techniques. We've added non-destructive evaluation to our process, giving our customers exceedingly precise outcomes.

5. Applications of Ceramic Strength Testing

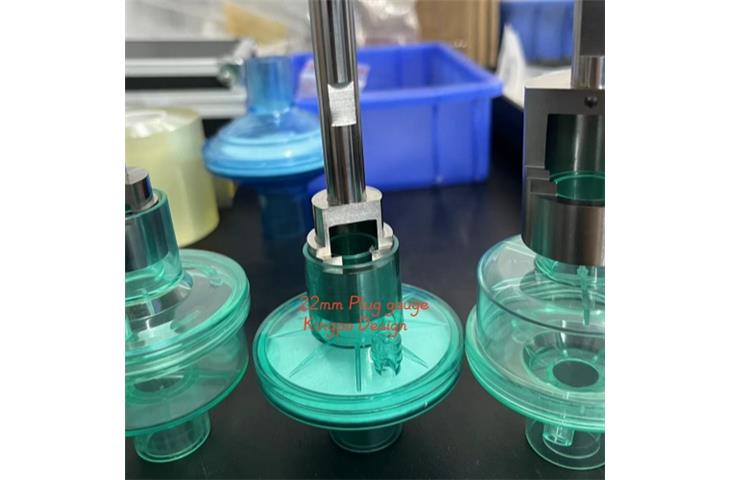

Ceramic strength testing has a ton of uses. From automotive components to medical devices like implants, how strong ceramics are is really important for making sure they work right and are safe. In medical care, for example, they use ceramics in orthopaedic implants because they're extraordinarily strong and function effectively with our bodies.

We've had success with a healthcare equipment firm. We made a material that was extremely robust and functioned effectively with our physique. It withstood rigorous exams, was introduced, and got positive feedback.

Related articles

- Optimizing Test Fixture C's GRF3C Probe: Why It Matters

- Essential Needs for Mandrel Testing Equipment

- Decoding the 9.8-3.3: A Comprehensive Insight

- Top 5 Paint Rub Tester Supplier Needs

- Promo: Mastering Color Fastness Test Machine Operations

- Purchase High Current Arc Ignition Systems

- China Pendulum Impact Tester: A Comprehensive Overview

- IEC62133 Battery Test Equipment: A Comprehensive Overview