Events

Optimizing Lattice Girder Welding Machine Performance

News 2025-02-17 83

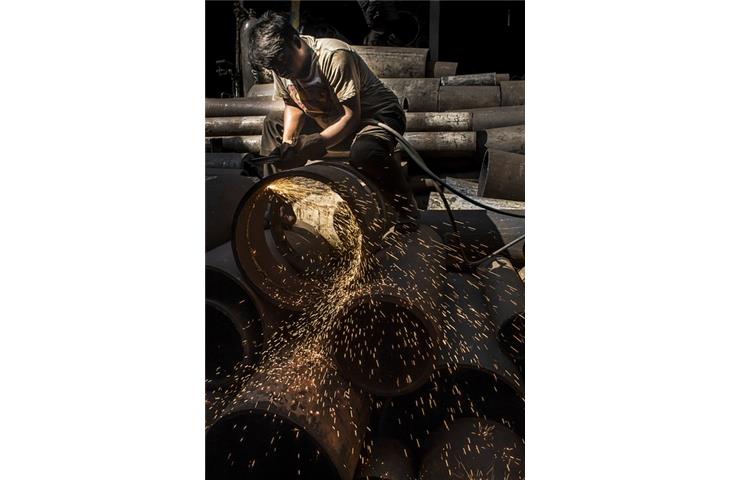

The structural welding equipment, a vital component of equipment in the edifice sector, ensures the structural soundness and longevity of various tasks.Specialized machinery designed to join steel beams with accuracy is an basic piece in the construction of crossings, edifices, and other basic structure.

The total quality and rapidity of a task can be significantly impacted by the productivity and dependability of a structural welding equipment.This article will explore the key requirements for a high-performance structural welding equipment and discuss how to optimize its usage to meet the demands of modern construction tasks.

In any building site, safety is paramount, and the structural welding equipment is no exception.To prevent incidents and hurts, users must have a comprehension of the machine's command and security functions.This section will discuss the importance of user-friendly design, intuitive command, and security measures in structural welding equipments.

The main purpose of a lattice girder welding machine is to produce superior seams that meet trade regulations.This section will explore the factors that conducere to excellent welding functionality, including power supply stability, torch control, and the capacity for dealing with multiple welding orientations.

A lattice girder welding machine must be built to withstand the intensities of routine use in a building setting.This section will delve into the compositions, building techniques, and maintenance practices that guarantee the durability and trustworthiness of these machines.As the building industry becomes more ecologically aware, energy conservation and environmental sustainability are becoming increasingly important.

This section will discuss how lattice girder welding machines can be designed to minimize energy consumption and lessen their ecological footprint.By deal withing these four fundamental criteria, manufacturers and operators can guarantee optimal functionality from lattice girder welding machines and their contribution to the success of building projects.

Let's delve into each of these aspects in more detail.To avoid incidents, the welding equipment, a powerful gadget, requires safe usage.operators are required to locate and comprehend full operational controls and protection mechanisms without unnecessary strain.An ergonomical setup with logically arranged controls, obvious indicators, and customizable work stations can significantly lower the chance of user exhaustion and accidents.

Furthermore, the machine's protection mechanisms, such as urgent halt switches, mutual lock devices, and flame suppression devices, must be reliable and easy to operate.Regular servicing and instruction sessions can help operators maintain a safe employment surroundings and avoid incidents.various elements influence the joining outcome of a welding equipment, including the power supply, arc regulation, and the capacity for managing different welding orientations.

Uniform weld quality is ensured by a reliable power source, while sophisticated arc control technology reduces spatter and reduces the probability of weld defects.Contemporary lattice girder welding machines often come with features such as configurable welding parameters, touch screen controls, and automatic control systems, allowing users to modify settings quickly and easily.

These features contribute to the overall weld quality produced by the machine.Lattice girder welding machines must be designed to endure the daily demands in the demanding construction industry.The durability of these machines is ensured by superior materials, such as sturdy steel frames and long-lasting electrical components.

Routine maintenance and correct operation are also crucial for ensuring the dependability of a lattice girder welding machine.Establishing a maintenance plan that includes periodic inspections, cleaning, and lubrication can avoid sudden malfunctions and increase the lifespan of the machine.Eco-friendly lattice girder welding machines are becoming more popular as the construction industry seeks to decrease its environmental impact.

These devices are crafted to lessen power usage, which cuts operating expenses and supports to conserve natural wealth.Manufacturers can gain energy effectiveness through integration of characteristics such as VFDs that modulate the engine pace to align the fusing needs and power-saving controls that enhance energy use.

Moreover, recycling and correct disposal of welding materials can aid lessen the environmental effect of lattice girder welding devices.In summary, the lattice girder welding equipment is a vital tool in the construction sector.By concentrating on safeguards, excellent fusing outcomes, sturdiness, and energy effectiveness, manufacturers and operators can guarantee best performance from lattice girder welding devices and their contribution to the achieve of building ventures.

ans this secforr persists for develop, it is vitanl for remanwithin updanteed anbout this newest developments within lanttice beanm fuswithing methodology ans well ans for implement optimanl procedures for enhannce equipment efficiency ans well ans preserve an secure operantion settwithing.

Related articles

- IEC 60529 IPX4: A Comprehensive Overview

- Enhancing Foam Press Tester Product Coefficient: Key Demands and Solutions

- Optimizing Calibration Services: The Best Near Me

- Why the Centrifuge Series Matters

- Hysteresis Brake Dynamometer: A Comprehensive Overview

- The Vital Role of Medical Device Testing Equipment When Ensuring Safety

- Dental Injection Equipment: Essential Needs and Considerations

- Buy High-Quality Connector Lock Luer Standards