Ф0.9mm IEC60695-11-5 IEC Test Equipment Needle Flame Test Apparatus

Ф0.9mm IEC60695-11-5 IEC Test Equipment Needle Flame Test Apparatus

- Model:

Ф0.9mm IEC60695-11-5 IEC Test Equipment Needle Flame Test Apparatus

IEC60695-11-5 Needle Flame Test Apparatus

Product information:

The Needle Flame Tester consists of a Ф0.9mm needle-shaped burner that tilts with the angel of 45°and provide it with butane gas. The fire hazard of the equipment when there is flammule inside the equipment that caused due to the fault condition is assessed by whether the specimen can be ignited or the combustion time and length. This tester conforms to the standard requirement of IEC60695-11-5,IEC60335-1.

The Needle Flame Tester is suitable for the research, production and quality testing department of lighting equipment, low-voltage apparatus, household appliance, machine tool electric appliance, electrical machine, electric tool, electronic instrument, electrotechnical instrument, electrical connector, electrical and electronical equipment and other components. It is also suitable for insulating material, engineering plastics or other solid combustion material industry.

Model specification and technical parameters (Optional for touch screen NF-2):

Parameter/ model | NF-1 |

Working voltage | 220V/50Hz |

Timing device | 9999X0.1S |

Combustor | Inner boreφ0.5mm ± 0.1mm ,OD ≤φ0.9mm ,L ≥ 35mm,stainless steel |

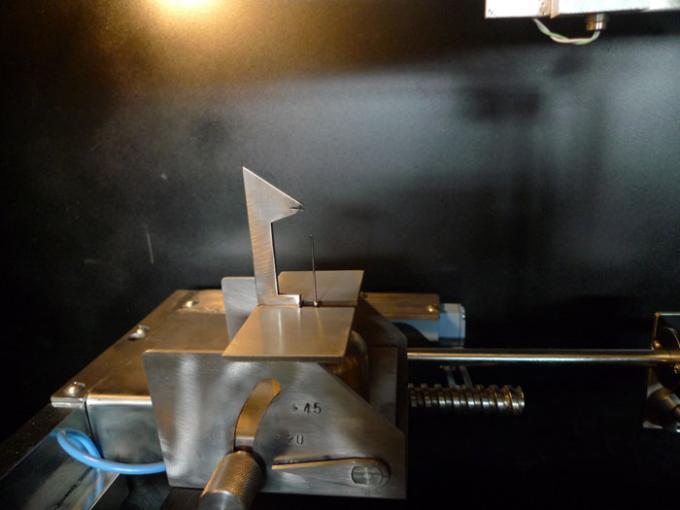

Combustion angle | tilt 45°( testing ) or vertical ( when adjust the height of the flame) |

Height of the flame | 12±1mm adjustable(with flame height gauge) |

Gas category | 95% butagas ( can use the bottled lighter gas) |

Range of temperature test | 0~1000℃ |

Flame warming requirement | From 100°to 700°,time for standard values within 23.5S±1S |

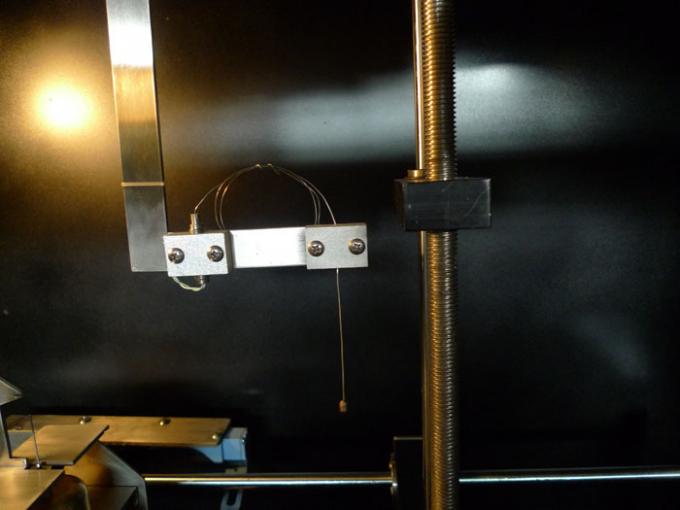

Temperature thermocouple | φ0.5 armour nickel-chromium/nickel aluminum wire K-Thermocouple |

Work shop | 0.5 cube,staunless steel case,black yogon background,(customizable0.75 cube,1cube) |

Testing process | Test procedure automatic control,independent air draft |

Volume size adjustment | Flowmeter adjustment |

Conforms to standard | GB4706.1-2005,GB5169.5-2008,IEC60695-11-5,IEC60335-1 |

Includes:

A white Pine Test Board and five Sheets of Tissue Paper

A flame height gauge

Consumables:

White Pine Test Board and Tissue Paper

Thermocouple Type K and Copper Block

Scope:

This part of IEC 60695 specifies a needle-flame test to simulate the effect of a small flame which may result from fault conditions, in order to assess by a simulation technique the fire hazard.

It is applicable to electrotechnical equipment, its sub-assemblies and components and to solid electrical insulating materials or other combustible materials.

One of the responsibilities of a technical committee is, wherever applicable, to make use of basic safety publications in the preparation of its publications.

General description of the test:

The test is performed to determine that, under defied conditions, the test flame does not cause ignition of parts, or that a combustible part ignited by the test flame has a limited duration of burning or a limited extent of burning, without spreading fire by flames or burning or glowing particles falling from the test specimen.

This test determines the effects on the test specimen of a small flame such as may arise from other ignited components and the relevant product specification shall specify the duration of flame application and the criteria for acceptance.

Description of the test apparatus

Burner:

The burner to produce the test flame shall consist of a tube at least 35 mm long with a bore of 0.5mm±0.1mm and an outer diameter not exceeding 0.9mm.

The burner is supplied with butane or propane gas having a purity of at least 95%. There shall be no air admitted to the burner tube.

Flame:

With the axis of the burner in the vertical position, the gas supply is adjusted so that the length of the flame is 12 mm±1 mm, when viewed in subdued light against a dark background (see Figure 1a). The flame shall be confirmed using the apparatus and procedure detailed in Annex A. The test time for the temperature to increase from 100℃±5℃ to 700℃±3℃ shall be 23.5s±1.0s.

IEC Test Equipment

IEC Test Equipment

IEC Test Equipment