Digital Control Lamps Light Testing Equipment Adjustment Devices Of Torsion And Bending Test According To IEC60598

Digital Control Lamps Light Testing Equipment Adjustment Devices Of Torsion And Bending Test According To IEC60598

- Model:

Digital Control Lamps Light Testing Equipment Adjustment Devices Of Torsion And Bending Test According To IEC60598

Digital Control Lamps And Lanterns Adjustment Devices Of Torsion And Bending Test According To IEC60598 Clause 4.14.3

Product information

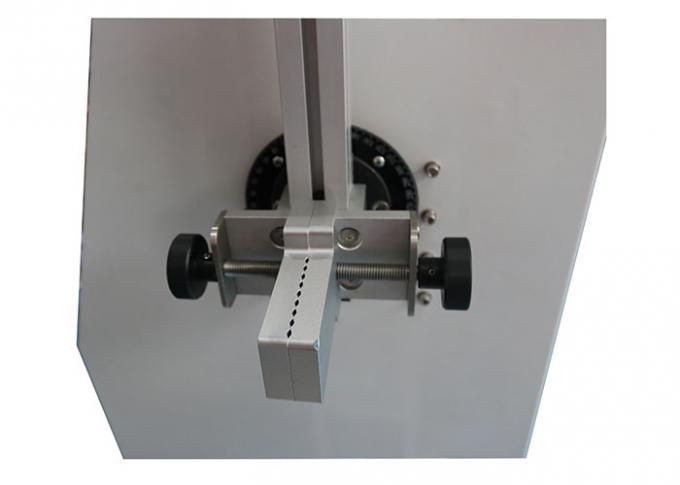

The device is used to detect adjustment device, and confirm to the IEC60598-1 clause 4.14.3.

The adjustment device, equipped with the appropriate cable or cord shall be operated in accordance with following table . A cycle of operation is a movement from one extreme of the range to the other and back to the starting position. The rate of movement shall not cause the device to heat appreciably and shall not exceed 600 cycles per hour.

For adjusting devices that consist of a flexible tube, the range of adjustment for this test is normally 135° in both directions from the vertical. However, where this adjustment cannot be achieved without using unreasonable force, the flexible tube is bent only to the positions where it will remain by itself.

Technical Parameters

| Item Name | Parameters |

| Angle | Positive and negative0-365°,Touch screen preset |

| Test rate | 1~10rpm,can be preset |

| Counting device | 0~999999 Six-bit memory preset number |

| Rotation center height | 1200mm |

| The maximum radius of gyration of the pendulum | R500mm |

| Maximum stroke of stretching action | 0-650mm |

| Power supply | 220V 50/60HZ |

| Controller | PLC Programmable Control |

| Drive motor | Stepper motor |

| Operation | Touch screen intelligent control (7 inch) |

| Test station | Single station |

| Standard | IEC60598.1 clause 4.14.3 |

Operation Procedures

Preparation work:

Access to 220V/50HZ power supply, turn the [POWER] switch on, and the [STOP] indicator light on, indicate the power accessed. Check the [E-STOP] button bounced or not. Install the sample load, install the power cord, and plug the power cord into the load socket according to the station.

Parameters Setting:

The following parameters should be set according to the relevant standards before starting the test.

【Test Times】: Set the Test Times.

【Manually Speed】: Enter swivel angle per second, suggested 10°-20°/s, the starting position cannot be well controlled if the manually speed is too fast.

【Swivel Times/Min】: Set swivel speed as per test requirement. The value bigger, the swivel speed faster, and vice versa.

【Swivel Angle】: Set swivel angle (full angle value) as per test requirement.

0 ° Position Confirmation

In the [0°Position Confirmation Interface], press [Manually Rotate Clockwise] or [Manually Rotate Counterclockwise]make the pointer of the manipulator swivel to position of 0° in dial(or any position), then press [Starting Position Confirmation] . Clear the value of [Current Position], and the starting position (0°) is confirmed.

Press [Manually Rotate Clockwise] or [Manually Rotate Counterclockwise] again, make the manage left starting position , check whether the display value in [Current Position] matches the value on the dial, after that, press [Homing], the manipulator will back to starting position, the display value in [Current Position] shown as 0. Starting position confirmed.

The 0° position can be set arbitrarily in any position of dial 360°base on requirement. Setting method same as above.