Electric Control Ingress Protection Test Equipment Road Vehicles Water Splash Test System Under 0 - 4°C

Electric Control Ingress Protection Test Equipment Road Vehicles Water Splash Test System Under 0 - 4°C

- Model:

Electric Control Ingress Protection Test Equipment Road Vehicles Water Splash Test System Under 0 - 4°C

ISO16750.4 Clause 5.4 Road Vehicles Water Splash Test System Splash 3s Under 0-4°C To Simulated Environments

A. SYSTEM introduction :

It conforms to ISO16750.4clause 5.4 :Ice water shock test ,It is Used For Safety Testing For Simulated Environments Of Electrical And Electronic Systems that may be subject to water splashing on various road vehicles.

B. technical parameters :

| Model | HH0807A |

| Test sample | The electrical and electronic system may be subject to water splashing on road vehicles |

| Studio size | 100×105×108(D×W×H)cm |

| Test bench area | φ60cm |

| Test bench bearing | 50kg |

| Test bench height adjustment | 20cm |

| temperature range | RT+10℃~150℃ |

| Heating rate | RT+10℃~150℃≤40min |

| Power | AC230V 50Hz or customized |

| Control system | Mitsubishi PLC Electric Control |

| Operation interface | 7 inch color touch screen operation |

| Test model | Splash water test |

| Test cycle | Default 100 cycles, 0-9999 can be preset |

| Splash time | 3s |

| Test liquid | De-ionized water or +5% NaCl or +3% Arizona Fine Dust |

| Test water temperature | 0-4°C |

| Cooling rate | 20℃~2℃≤60min |

| Water flow | 3-4L/3s |

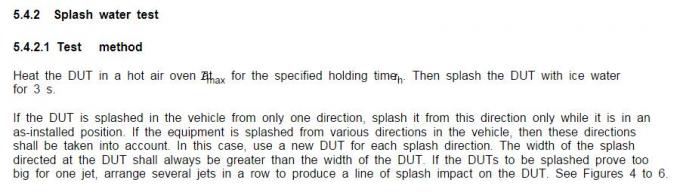

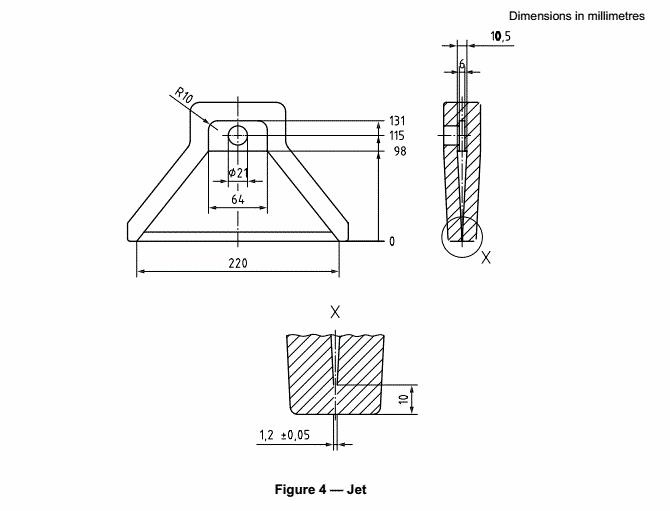

| Distance between jet nozzle and the test sample | 325±25mm |

| Orientation of the splash water | The sample is placed on the turntable according to the actual use, according to the actual situation to choose the positioning (single-direction splash) or rotation mode (multi-directional spray) |

| DUT heating | Heating system |

Introduction to structural design

This product is made of high-quality materials, processed by advanced processing equipment, and the surface of the outer casing is sprayed, beautiful and flat. The color is coordinated, the arc is designed, and the lines are smooth and natural. The liner is designed to be a confined space during work and is made of imported high quality stainless steel. The indoor sample holder and other accessory accessories are made of stainless steel, with reasonable design and durability. Under the premise of complying with national standards, the equipment is more practical and easy to control based on the stability of all aspects. Moreover, the device has the characteristics of easy installation, simple operation, and easy routine maintenance.

1. The outer casing of the equipment is made of high-quality galvanized steel plate CNC machine tool, and the surface of the outer casing is sprayed, which is more smooth and beautiful.

2. The inner tank is SUS316 high-quality stainless steel mirror panel; in order to facilitate the recycling of the test medium and the cleaning after the Zui, the bottom of the equipment studio is designed as a funnel;

3. Equipment cleaning: There are multiple high temperature anti-corrosion cleaning spray heads inside the equipment studio. After the equipment program is finished, the solenoid valve is opened, and the cleaning nozzle connected with tap water is a multi-directional washing studio;

4. Nozzle moving device: The nozzle is fixed on the upper and lower brackets with thermal insulation layer. When the temperature is high, the bracket moves out of the working chamber and moves quickly into the working room during spraying;

5. Flowmeter: The electronic flowmeter is used to measure the flow of the test water flow, which can control, adjust, display and accumulate the flow. Output 4~20mADC signal through the converter, connect with the central controller, be controlled by it and display;

6. Insulation material: high-density fiberglass cotton to ensure insulation performance and maintain a stable indoor temperature;

7. The door is provided with a transparent window for observing the change of the indoor sample. The observation window is made of multi-layer hollow tempered glass;

8. The mixing system adopts long-axis fan motor and high-low temperature resistant stainless steel multi-wing impeller to achieve vertical convection vertical diffusion cycle, so that the temperature and humidity in the laboratory are uniform and stable;

9. Double-layer high-temperature resistant high-strength sealing strip is used between the door and the cabinet to ensure the sealing of the test area. The inner door material of the door is made of stainless steel, and the door handle is made without reaction, which makes the operation easier;

10. Test hole (left side of the machine) can be used for external test power cable or signal cable (aperture 50mm);

11. The pump and refrigeration system of the equipment are installed at the bottom, and the compressor is imported from Taikang brand in France to ensure the cooling effect and reliability.

12. Install high-quality fixed-position PU movable wheel on the bottom of the machine, which can easily move the machine to the designated position and fix the caster after the Zui;

13. The control part of the equipment is designed on the right side of the equipment. It is distributed with temperature controller, control switch, water tank, etc. It is easy to operate, simple and easy to maintain.

Circuit control and protection system

With 7-inch LCD touch screen controller, PLC control can control temperature, pump and flow and test time respectively; the flow is directly displayed on the touch screen.

1. Importing components;

2. No fuse protection switch;

3. Overload, leakage, fully sheathed terminal blocks;

4. With automatic shutdown and other protection;

Cooling System

1. Compressor: fully enclosed France Taikang;

2. Refrigeration method: mechanical refrigeration;

3. Condensation mode: forced air cooling;

4. Refrigerant: R404A (environmentally friendly);

5. The whole system pipeline is tested for ventilation and pressure 48H leak test;

6. The heating and cooling system is completely independent;

7. Internal spiral refrigerant copper tube;

8. Slope evaporator;

9. Dry filter, refrigerant flow window, repair valve, oil separator, solenoid valve and liquid storage tank are all imported original parts;

Conditions of Use

1. Ambient temperature: 5 ° C ~ +32 ° C

2. Ambient humidity: ≤85%

3. Power requirements: AC380 (±10%) V/50HZ three-phase five-wire system

4. Pre-installed capacity: about 16KW

Picture for reference:

Ingress Protection Test EquipmentIngress Protection Test Equipment

Ingress Protection Test EquipmentIngress Protection Test Equipment

Ingress Protection Test EquipmentIngress Protection Test Equipment