Horizontal / Vertical Burning Test Chamber Spray Tank , 180×560mm Specimen Holder

Horizontal / Vertical Burning Test Chamber Spray Tank , 180×560mm Specimen Holder

- Model:

Horizontal / Vertical Burning Test Chamber Spray Tank , 180×560mm Specimen Holder

Horizontal And Vertical Burning Test Chamber Flammability Testing Equipment

Principle:

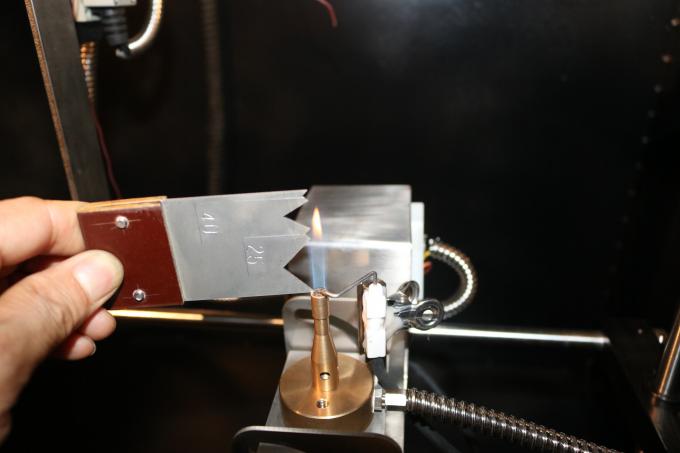

A defined ignitions flame from a specified burner is applied for a defined period of time to textile specimens which are vertical oriented. The flame spread time is the time in seconds for a flame to travel between maker threads located at defined distances. Other properties relating to flame spread may also be observed, measured and recorded.

Scope and field of application:

This international standard specifies a method for the measurement of flame spread properties of vertically oriented textile fabrics intended for apparel, curtains, draperies and large tents including awnings and marquees, in the form of single or multicomponent (coated, quilted, multilayered, sandwich construction and similar combinations) fabrics.

The test results will not apply to situations where the oxygen supply is insufficient or when the heat is too long in the fire.

Test standard:

ISO6941 Textile fabrics-Burning behaviour- vertically oriented specimens.

Technical Parameters:

| Test box | SUS304 Stainless steel production or spray tank, 1200*600*1200mm |

| Template | 180×560mm |

| Specimen holder | 180×560mm |

| Specimen | (560×170)±2mm,warp direction and across warp each are three |

| Flame height | 40±2mm |

| Ignition time | 5s / 15s |

| Mark line distance | 220mm,150mm,150mm |

| The angle between the axis of the ignition device and the surface of the specimen | 30°/45°/ 90° |

Conditioning of test specimens

Condition test specimens in one of the following ways:

a) In the standard temperate atmosphere of 20±2℃ and (65±2)% rh in accordance with ISO 139;

b) Drying in an oven at 105±2℃ for not less than 1 h, then cooling in a desiccator for at least 30 min; or

c) Any other conditioning atmosphere as agreed by the interested parties.

Procedure

1. Carry out the test in an atmosphere having a temperature between 10 and 30℃ and a relative humidity between 15% and 80%.

2. Light the burner and preheat it for 2 min. Adjust the flame height to 40±2 mm measured as the distance between the top of the burner tube and the tip of the yellow part of the flame when the burner is vertically oriented and the flame is viewed in dim light.

3. If testing is not being performed immediately, place the specimens in sealed containers until testing begins. Begin testing each specimen within 2 min of removing it from the conditioning atmosphere or sealed container.

4. Place the specimen on the pins of the test frame, making certain that the pins pass through the points marked off from the template and that the specimen is at least 20 mm removed from the frame. Fit the frame on the support so that the specimen is vertical.

5. Attached the marker threads horizontally in front of the specimen at the location shown in Figure 1. At each location, mount a loop of thread so that the two segments are spaced 1 mm and 5 mm from the plane of the front of the specimen. Attach each loop to a suitable timing device. Impose sufficient tension to the thread to maintain its position relative to the specimen.

6. For all fabrics intended for apparel, curtains and drapes, position the burner as described in 8.6.1. Where fabrics intended for curtains and drapes fail to ignite with the burner in this position, the burner position described in 8.6.2 is used if required by the relevant fabric specification. For fabrics for large tents, awnings and marquees, the burner position described in 8.6.2 is used.

Flammability Testing Equipment

Flammability Testing Equipment

Flammability Testing Equipment