IEC60335-2-17 Programmable Temperature Humidity Chamber PTH-1000 (150L) ,-40 ℃~ +150 ℃,20 %RH~ 98 %RH

IEC60335-2-17 Programmable Temperature Humidity Chamber PTH-1000 (150L) ,-40 ℃~ +150 ℃,20 %RH~ 98 %RH

- Model:

IEC60335-2-17 Programmable Temperature Humidity Chamber PTH-1000 (150L) ,-40 ℃~ +150 ℃,20 %RH~ 98 %RH

IEC 60335 Programmable Temperature Humidity Chamber PTH-1000 (150L) ,-40 ℃~ +150 ℃,

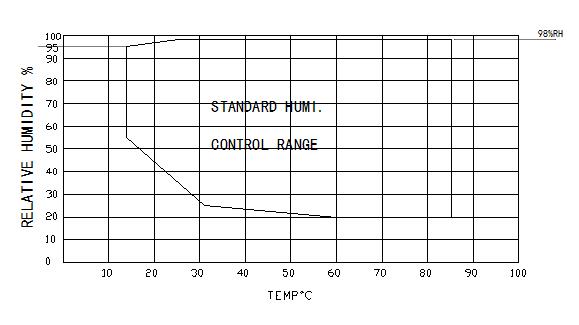

20 %RH~ 98 %RH

Standard

IEC60335-2-17, Clause 21.110.3, Clause 21.111.2.

Application

It is used to process the aging test for the blanket’s flexible fabric parts.

Test sample

Blanket’s flexible fabric parts.

Feature

Box type

Parameters

| Product Name | Programmable Temperature Humidity Chamber |

| Volume, size and weight | |

| Working Volume | 150L (can be customized) |

| Inner size | W500mm × H600mm × D500mm |

| Outer size | W1020mm × H1000mm × D1460mm |

| Weight | 300KG |

| Performance | |

| Test environmental conditions | Environmental temperature +5~+28℃, relative humidity≤85%, under the condition that no sample inside the test chamber |

| Test method | According to IEC60068-2, IEC60598-1 |

| Temperature range | -40℃~+150℃ |

| Temperature control precision | ±0.2℃ |

| Humidity control precision | ±2.5% RH |

| Temperature uniformity | ±2℃ |

| Humidity uniformity | ±3.0% RH |

| Heating up time | 3℃/min (Average heating up rate) |

| Cooling down time | 1℃/min (Average cooling down rate) |

*Note: Please refer to below humidity use range chart!

4. Temperature and humidity control accuracy: ±0.2℃; ±2.5%RH.

* To guarantee above 2~4 performance, should be measured 30 minutes after the temperature sensing measurements is stable!

5. Temperature and humidity distribution uniformity: ±2℃; ±3%RH.

*Note: To guarantee below 6~11 performance, the measuring positions should be each wall’s 1/6 positions of the test zone, and should be measured 30 minutes after the temperature is stable!

6. Heating time: Heating from the room temperature to 150℃, the total heating time is 50 mins (under non-load state).

7. Cooling time: Cooling from the room temperature to -40℃, the total cooling time is 40mins (under non-load state).

8. Inner chamber dimensions: test area: 50×60×50cm(W×H×D).

*Note: The volume of placing samples should not exceed 2/3 of the capacity of the test zone.

9. Equipment installation space: at least 920×1600×870cm(W×H×D).

10. Test chamber door: 80 × 105 cm(W×H), total 1.

11. Power source: AC 1 ∮ 220 V 50 Hz MAX 40 A

Picture for reference

IEC Test Equipment

IEC Test Equipment

IEC Test Equipment