IEC60695 Flammability Testing Equipment , 0.5m³ Needle - Flame Tester PLC Control

IEC60695 Flammability Testing Equipment , 0.5m³ Needle - Flame Tester PLC Control

- Model:

IEC60695 Flammability Testing Equipment , 0.5m³ Needle - Flame Tester PLC Control

0.5m³ Needle-Flame Tester Plc Control The New IEC60695 Flammability Test Machine

Products Introduction

This part of IEC 60695 specifies a needle-flame test to simulate the effect of a small flame which may result from fault conditions, in order to assess the fire hazard by a simulation technique.

It is applicable to electrotechnical equipment, its sub-assemblies and components and to solid electrical insulating materials or other combustible materials.

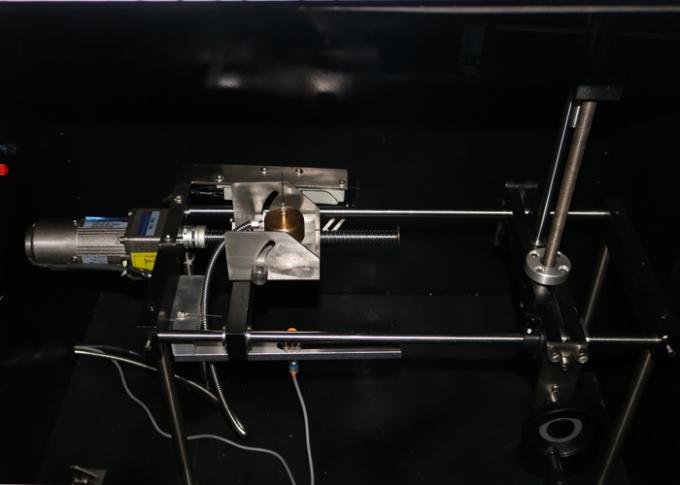

The structure of this tester is stainless steel plate and high-grade spraying outside chamber, using the most advanced PLC control, to achieve intelligent control, standard equip with TFT true color LCD, can achieve upgrade of the customer's humanized operation interface, and truly achieve the comparison result of the international.

The burner to produce the test flame shall consist of a tube at least 35 mm long with a bore of 0.5mm±0.1mm and outer diameter not exceeding 0.9mm. The burner is supplied with butane or propane gas having a purity of at least 95%. There shall be no air admitted to the burner tube. To evaluate the possibility of spread of fire, for example by burning or glowing particles falling from the test specimen, a layer of the material or components normally surrounding or situated underneath the test specimen and the surrounding material or components when the test specimen is mounted as in normal use.

The test flame is positioned so that the tip of the flame is in contact with the surface of the test specimen. The test flame is removed after the specified time.

If the test specimen drips molten or having flaming material during the application of the flame, the burner may be tilted up to 45°from the vertical to prevent material from dripping into the burner tube while maintaining an 8mm±1mm spacing between the centre of the top of the burner and the remaining portion of the test specimen, ignoring any strings or molten material.

It is applicable to lighting, low-voltage electrical appliances, household appliances, machine tool electric appliance, electric motor, electric tools, electronic instruments, electrical instruments, electrical connector, such as electrical and electronic equipment and parts, components, including insulation materials, engineering plastic or other solid combustible materials.

Parameters

| Control mode | Using the most advanced PLC control, to achieve intelligent control |

| Display mode | True color LCD (standard equip 7 Inch display control touch screen) |

| Chamber Structure | Stainless steel plate with high-grade paint |

| Button switch | Top grade button |

| Combustion gas | Butane or propane gas having a purity of at least 95% |

| Flame application time | 0-9999.9s can be preset |

| Flame duration | 0-9999.9s display, automatic recording, manual pause |

| Gas flame temperature gradient | 100℃ ± 2℃ ~ 700℃ ± 3℃ ( room temperature~ 999℃ ) ,23.5s±1.0s (1s ~ 999.9s) |

| Flame height | 12mm ± 1mm ( Adjustable ) |

| Combustion angle | Tilt 45°( testing ) or vertical ( when adjust and measure the height of the flame) |

| Needle burner | Stainless steel,bore diameter:Φ 0.5mm ± 0.1mm,outer diameter ≤Φ 0.9mm ,length≥35mm |

| Thermocouple | Φ 0.5 armour nickel-chromium / nickel aluminum wire K type thermocouple, temperature resistance 1100° |

| Temperature sensing delay | 1.7S |

| Test space | ≥ 0.5m³, black yogon background |

| Dimensions | L1100mm × W530mm × H1150mm ,Exhaust aperture:Φ100mm; |

| Power supply | 220V /50Hz, 0.5kVA |

| Standard | IEC60695-11-5, IEC 60695-2-2 |

Attentions

To prevent the leakage of gas.

To prevent the combustion and explosion accident.

To prevent the inhalation of toxic gas or smoke.

To prevent the damage of the toxic residual to damage the human health.

To prevent the blockage of the combustion tube by the foreign object.

To lubricate the moving parts regularly.

In an emergency, turn off the power switch on the device panel, stop the system operation, clear the faults.

Please do not change some default parameters arbitrarily!

For more detail information, please refer to the user manual.

If there are any doubts, please contact the supplier.

Maintenance

A. The device is made of metal, should be prevented from dust and moisture environment.

B. Cut off the power when it is in non-working status.

Flammability Testing Equipment

Flammability Testing Equipment

Flammability Testing Equipment