IEC60950.1 Dropping Ball Impact Testing Machine With 25g / 29g Steel Ball

IEC60950.1 Dropping Ball Impact Testing Machine With 25g / 29g Steel Ball

- Model:

IEC60950.1 Dropping Ball Impact Testing Machine With 25g / 29g Steel Ball

IEC60598.1 And IEC60950.1 Dropping Ball Test Apparatus With 25g / 29g Steel Ball

Product introduction:

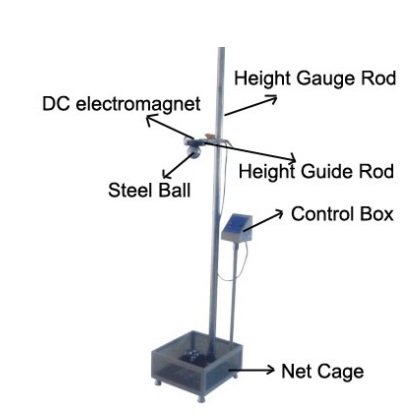

The ball drop test apparatus is mainly used to test plastic, ceramics, glass fiber and other materials. Choose the corresponding steel ball according to related standard requirements, then adjust it to be a certain height, and then make it fall freely to impact the test sample. After that, judge the quality of the test sample according to the degrees of the damages.

Technical parameters:

| Power Supply | 120V, 60Hz |

| Ball Drop Control Method | Controlled by DC electromagnetic |

| Weights Of Steel Ball | 25g*10pcs, 29g*10pcs |

| Drop Height | 0~2000mm adjustable |

| Dimensions | 50cm*45cm*220cm |

| Weight | 32KGS |

Method of usage:

A.Access to power supply, then turn on the power switch.

B.Fix the test sample on the plate inside of the net cage according to its size, then adjust the height guide rod to the required height along the height gauge rod.

C.Press “Start”, and adsorbent the steel ball is in the middle of DC electromagnet, then press “Drop”, the steel ball fall freely to impact the test sample.

D.Take out off the test sample, observe the degree of the damage, and judge the quality of the test sample accordingly.

Maintenance:

A. Clean the test device often, prevent it from dusty and moist environment.

B. Do not put any chemical items on the surface of the machine.

C. Should be often sprayed with rust oil on the machine surface.

Precautions:

A. Operator keeps head away from the test area, so as to avoid head injuries.

B. When testing glass, be careful of the broken glass, operator is recommended to wear the protective glasses, or take other measures to avoid any injury to the eyes.

C. Requires professional personnel custody and testing, the test device should be grounded.