IEC Test Equipment , IEC60884 Clause 24.7 Insulation Sleeves Plug Pins Abrasion Test Apparatus

IEC Test Equipment , IEC60884 Clause 24.7 Insulation Sleeves Plug Pins Abrasion Test Apparatus

- Model:

IEC Test Equipment , IEC60884 Clause 24.7 Insulation Sleeves Plug Pins Abrasion Test Apparatus

IEC60884 Clause 24.7 Insulation Sleeves Of Plug Pins Abrasion Test Apparatus Of IEC Testing Equipment

Standard: IEC 60884-1 2013 clause 24.7 and figure 28, BS1363-1 figure 9

Application: This device is use for test the abrasion resistance strength of insulation sleeve of plug pins

Test sample: Insulation Sleeve of plug pins

Feature: Device consists of a horizontal placement of the beam and the linear movement of the fixture seat, wherein, beam ends with diameter 1mm short steel wire is bent into a U-shaped head (U shape of two vertical fixed on the beam), wire U-shaped bottom is 6mm linear part. Compress the 6mm hemline on the plug insulation sleeve, the motor drives the mounting bolt clamp seat to do reciprocating movement back and forth, conducting the abrasion test to insulation sleeve of plug pins.

Parameters:

| Item | Parameter |

| Power supply | AC220V 50Hz |

| Station | Single station |

| Test times | 1~999999, preset |

| Rate of abrading | 30 movements per minute |

| Load | 4N |

| Stroke | 9mm, about 7mm scratch on insulation sleeve |

| Steel wire | Diameter 1mm, effective length 6mm |

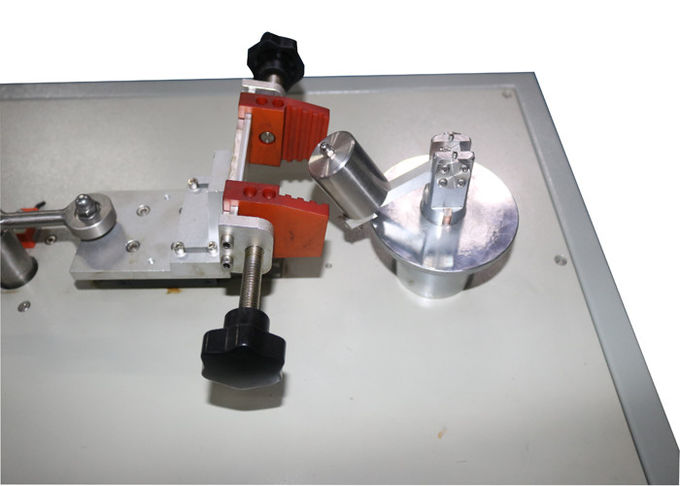

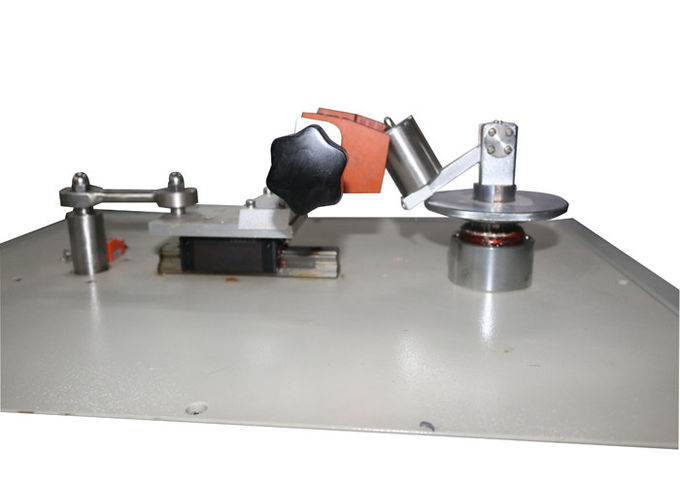

Picture for reference:

Standard description:

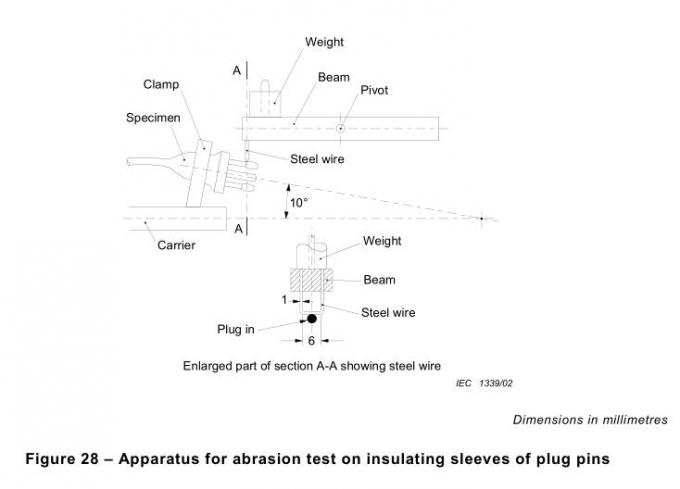

Plug pins provided with insulating sleeves are subjected to the following test by means of an apparatus as shown in figure 28.

The test apparatus comprises a horizontal disposed beam .which is pivoted about its centre point ,A short length of steel wire ,1mm in diameter and bent into a U-shape ,the base of the U being straight ,is rigidly attached ,at both ends ,to one end of the beam ,so that the straight part projects below the beam and is parallel to the axis ogre the beam pivot .

The plug is held by a suitable clamp in such a position that the straight part of the steel wire rests on the plug PIN ,perpendicular to it .The PIN slopes downwards at an angle of 10°to the horizontal .

The beam is loaded so that the wire exerts a force of 4N on the pin.

The plug is moved backwards and forwards in a horizontal direction in the plane of the axis of the beam ,so that the wire rubs along the pin, The length ogre the pin thus abraded is approximately 9mm ,of which approximately 7mm is over the insulating sleeve ,the number ogre movements is 20000(10000 in each direction )and the rate of operation is 30 movements per minute .

The test is made on one pin of each specimen .

After the test ,the pins shall show no damage which may affect safety or impair the further use of the plug ,in particular ,the insulating sleeve shall not have punctures or rucked up .

About Us:

Guangzhou Hongce Equipment Co., Ltd is a leading company in inspection equipment industry, established in 2003 and located in Guangdong, China. Our company introduced advanced equipment, combined with the most advanced technology production processes, strict quality control system to control the entire process of production. The company combined with a number of high-tech management personnel and advanced equipment, and together with the modern management, computer design and control, our products has reached the international advanced level. The company set R&D design, production, sales as one, specializing in producing electric wire inspection equipment of plug and socket, mechanical robustness testing equipment of electronics, inspection equipment of electronics’ on-fire danger, testing indicator of anti-electric shock and solid objects' entry, general inspection equipment, and other non-standard testing equipment. Our products enhance good selling at home and abroad, and have established supply relationships with a number of well-known companies.