IK Code Impact Testing Machine / Stainless Steel Pendulum Swinging Hammer Test Apparatus

IK Code Impact Testing Machine / Stainless Steel Pendulum Swinging Hammer Test Apparatus

- Model:

IK Code Impact Testing Machine / Stainless Steel Pendulum Swinging Hammer Test Apparatus

IK Code Impact Testing Machine Stainless Steel Pendulum Swinging Hammer Test Apparatus

Standard

IEC60068-2-75 Environmental testing – Part 2: Tests – Test Eh: Hammer tests, IEC60068-2-63, IEC62262 Degrees of protection provided by enclosures for electrical equipment against external mechanical impacts (IK code), IEC60439-5 Low-voltage switchgear and controlgear assemblies - Part 5:Particular requirements for assemblies for power distribution in public networks

Application

This device is suitable for mechanical impact strength test to electric cabinets and other sheet metal, shell of Non metal electric energy metering cabinet, substation cable switchboard and cable junction box

Test sample

The shell of electric energy metering cabinet, substation cable switchboard and cable junction box and similar equipment

Feature

Equipment using the car structure, can be moved left and right, forward and backward, the upper and lower impact point height adjustable, and the impact angle 0-90°adjustable. The device is a low energy pendulum impact device for 2J and above.

Parameters

| Model | HC9921A |

| Pendulum | Length: 1000mm; external diameter: 9mm; steel pipe wall thickness: 0.5mm. Composition of the equivalent mass with impact element |

| Impact point | Up and down adjustable, stroke 200-1200mm, height can be customized |

| Impact element | 2,5,10,20J impact hammer |

| Drop height | Scale display |

| Release mode | Mechanical |

| Dimension | 950*550*2700mm |

Impact energy, equivalent mass and drop height table

| Energy/J | 2 | 5 | 10 | 20 | 50 |

| Equivalent mass /kg | 0.5 | 1.7 | 5 | 5 | 10 |

| Drop height ±1%mm | 400 | 300 | 200 | 400 | 500 |

Notes: 1. See note in IEC 60068-2-75 3.2.2

| |||||

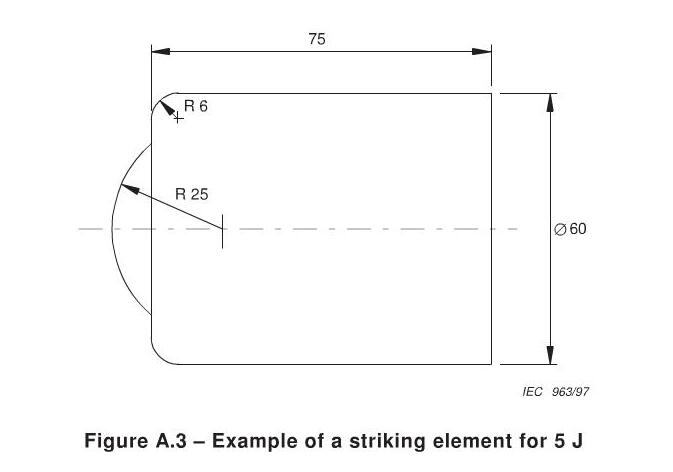

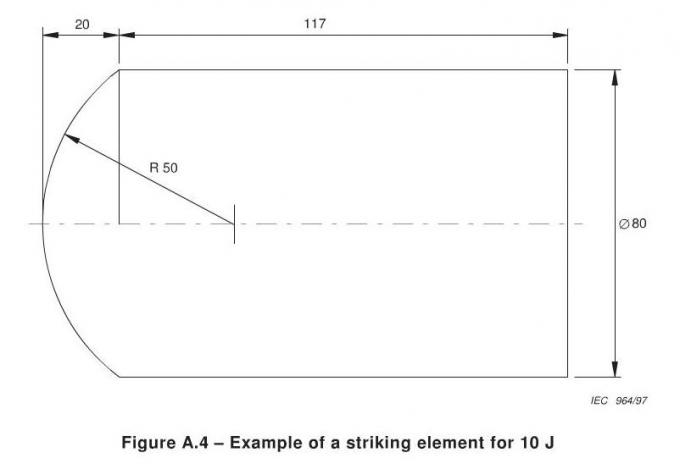

Co-ordinated characteristics of the striking elements

| Energy /J | ≤1 ±10% | 2 ±5% | 5 ±5% | 10 ±5% | 20 ±5% | 50 ±5% |

| Equivalent mass ±2%kg | 0.25(0.2) | 0.5 | 1.7 | 5 | 5 | 10 |

| Material | Polyamide 1) | Steel 2) | ||||

| R/mm | 10 | 25 | 25 | 50 | 50 | 50 |

| D/mm | 18.5(20) | 35 | 60 | 80 | 100 | 125 |

| f/mm | 6.2(10) | 7 | 10 | 20 | 20 | 25 |

| r/mm | - | - | 6 | - | 10 | 17 |

| l/mm | To be adjusted to match the equivalent mass, see Annex A. | |||||

1) 85≤HRR≤100, Rockwell hardness according to ISO2039-2. 2) Fe490-2, according to ISO1052; Rockwell hardness according to ISO6508. | ||||||

| NOTE- The values shown in the brackets for the equivalent mass and the diameter of the striking elements for the energy value equal to or less than 1 J are those in the current test Ef. The values currently in test Eg are also shown for these two parameters. For co-ordination purpose, the values in brackets will be deleted fives years from the publication of this standard. | ||||||