Products

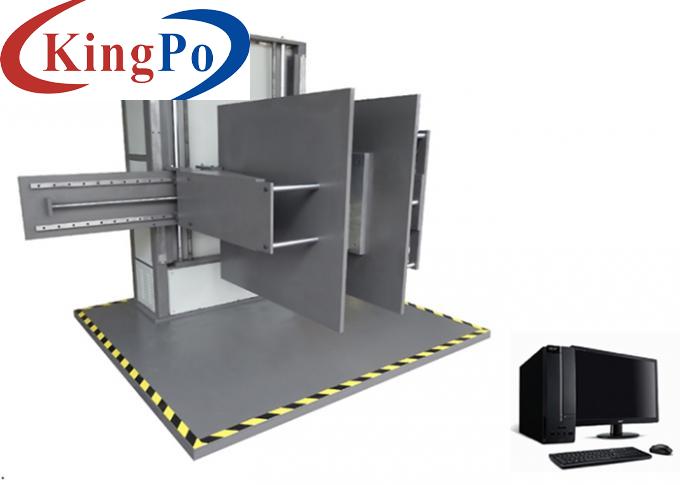

Programmable Electrical Appliance Hydraulic Pressure Test Equipment

Products Description

IEC 60335 Comprehensive Hydraulic Pressure Test System

Product information:

This hydraulic pressure test system can match many standard testing requirements, such as:

IEC 60335-2-5 cl.22.101 1.2 MPa or higher

IEC 60335-2-7 cl.22.101 2.0 MPa or higher

IEC 60335-2-21/35 22.47 twice the rated pressure (1.4MPa common from 0.6MPa inlet pressure, 2MPa for open water heater), 22.103 0.1MPa from rated of PRV

IEC 60335-2-24 cl.22.7, etc.

Technical parameters

0.5-32Mpa or 42Mpa

(stepless adjustable, can be customized)

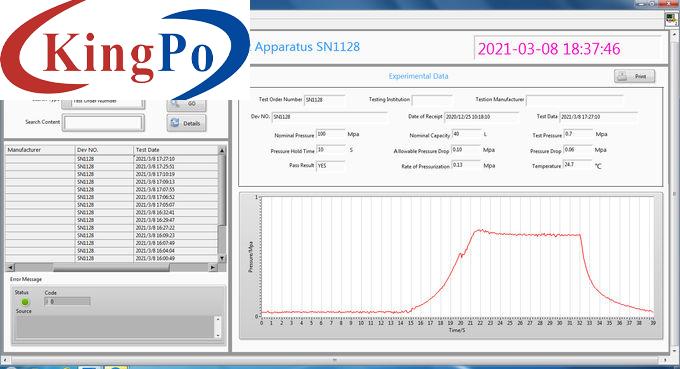

The typical test procedures equipped are:

① Constant speed boost-blasting;

Control features:

The software is written by force control configuration software or LABVIEW (computer control)

Realize the computer control function, operator can freely set the water filling and exhaust time, the pressure holding time, the inflation cleaning time, and the test pressure. During the experiment, operator can arbitrarily set a single or multi-stage pressure holding test. The speed can be kept constant, stepless adjustment can be realized, test data and curve parameters can be displayed in real time, test results can be automatically saved, and test reports can be printed at will. (computer control).

Pressure range

Test medium

Clean liquid water

Test station

1 station (can be customized)

Allowable medium temperature

RT+5°C-80℃ (can be customized)

Power source

Gas-liquid booster pump

Drive air pressure

0.2-0.8Mpa

Pneumatic duplex

UFRL04

Outlet flow

0.5L/min

High pressure pipe joint

Stainless steel tube, ferrule

Solenoid valve

Sanlixin

Clean water tank

Stainless steel

Electronically controlled proportional valve

SMC

Control method

Computer

High pressure gauge

KEMAI

Max. pressure test

32Mpa

Computer

Advantech Industrial Computer

Chamber appearance

Q235 spray treatment

② Constant speed boost-hold pressure-blasting;

③ Constant speed boost-pressure hold-pressure relief;

④ Constant speed boost-pressure hold-constant speed boost-pressure hold-until blasting (incremental boost).