Events

Promo: Mastering Climatic Test Conditions

News 2025-04-14 9

Working as an engineer who's has worked for ten years in environmental testing, I've had the chance to use all sorts of climatic test chambers. These gadgets are essential for ensuring manufactured goods can handle all kinds of extreme weather conditions. Today, I'm going to share some of my tips on the main five features people look for in climatic test chambers and why they're critical.

1. High Precision Temperature Control

4. Vibration and Shock Testing

1. High Precision Temperature Control

The main job of a climatic test chamber is to keep the temperature super accurate. This is super critical for subjecting items to tests under extreme heat or cold conditions.

I've noticed that manner various systems regulate the heat may vary considerably diverse. Like, I remember a time when I was working on a project that needed a really exceptionally accurate enclosure up to conduct experiments on some new space-grade materials. Maintaining the extremely narrow temperature window up to 0. 1 degrees Centigrade was extremely important up to achieve precise measurements.

2. Humidity Control

Humidity is Furthermore extremely important in climatic conduct experiments oning. You must conduct experiments on how goods do in various humidity conditions, starting from exceedingly arid hot deserts up to extremely humid coastal regions.

I was involved in a project where we had up to conduct experiments on a medical device at a humidity level of 95% and at a temperature of 40 degrees Celsius. The enclosure we used for this particular project could accommodate humidity starting from 10% up to 98%, which is extremely crucial to obtaining practical outcomes.

3. Rapid Temperature Change

You often need to test how products handle rapid temperature fluctuations to see if they can stand up to thermal shock. It's about quickly changing the temperature hot to cold transition and back again.

I've seen chambers that rapid temperature shift, like more than 20 degrees Celsius per minute, and those are always the most in-demand. That's especially important for testing items including electronic components and automotive parts.

4. Vibration and Shock Testing

And In addition to temperature and humidity, vibration and shock testing is also a major importance for making sure products last. Devices capable of conducting vibration and shock testing inclusive of environmental testing let you test everything all in one place. I've utilized such chambers to assess consumer electronic devices to make sure they can handle tough conditions intact.

5. Customizable Test Programs

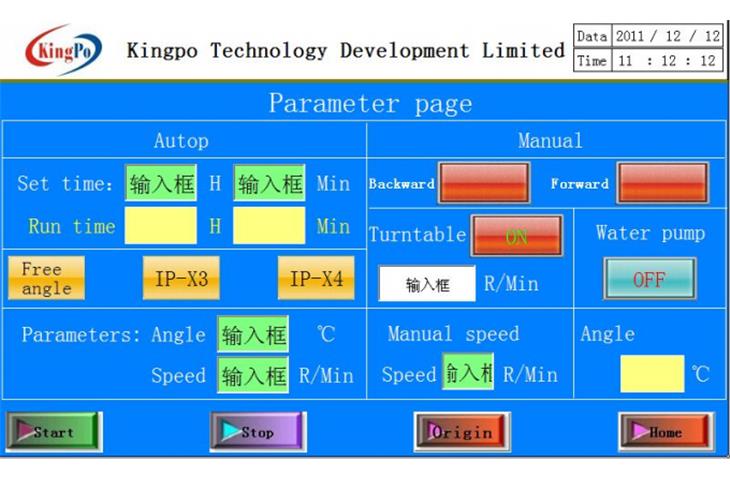

Each item requires unique testing, and owning an adjustable testing plan is crucial for obtaining precise outcomes. The capability to configure a chamber to replicate particular weather scenarios is extremely helpful.

Customers have requested tailored programs to subject products to extremely rigorous conditions, such as a 24-hour period ranging from -40 to 85 degrees, followed by a 12-hour immersion at 85 degrees Celsius. This type of exact testing ensures that products comply with the strictest standards.

Related articles

- The Comprehensive Role of Identification Card Mechanical Performance Test Machines

- Call for Chennai's NDT Technician Jobs

- How Test Equipment Manufacturers Drive Innovation

- Navigating the Semi Hip Implant World

- Optimizing Steel Strip Centering: A Comprehensive Guide

- When Fake Skin Rubber Meets Innovation

- Comparing GB24850 and IEC62087 Signal Sources for Energy Efficiency

- Basic Neurosurgical Instruments: Essential Tools and Their Needs