Events

Purchase High Current Arc Ignition Systems

News 2025-04-10 21

High current arc ignition is crucial in numerous industries, such as welding and plasma cutting processes. We will delve into five key requirements for high current arc ignition, and we will share our practical experiences and the knowledge we have gained. The focus is on aiding you in making informed decisions.

1. Efficient Arc Ignition for Welding Applications

2. Enhanced Safety Measures in Arc Ignition Systems

3. Customization and Scalability for Industrial Needs

4. Energy Efficiency and Cost Reduction

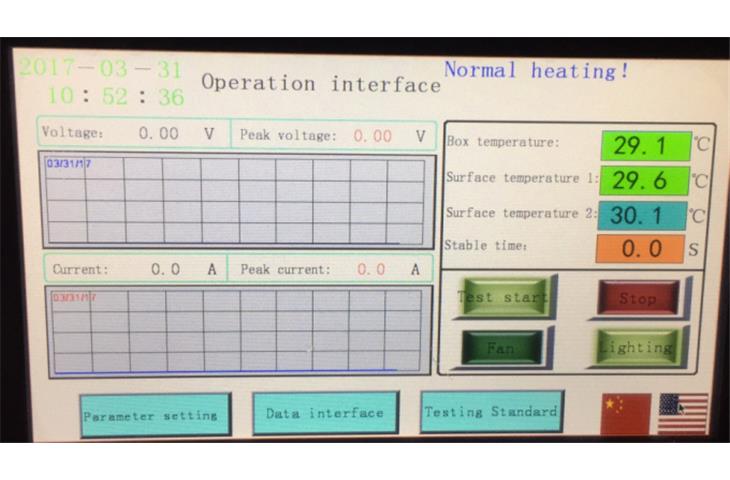

5. Integration with Advanced Control Systems

1. Efficient Arc Ignition for Welding Applications

Welding is one of the most common applications of high current arc ignition. You gotta have a reliable system that can light that arc up and keep things stable when welding.

Take TIG welding, for instance. It's all about that powerful electric arc to stick metal pieces together. We've seen it work, a good powerful electric arc system really steps up welding and cuts down on waiting time.

2. Enhanced Safety Measures in Arc Ignition Systems

You need to handle these systems right, because they can be dangerous if not. Safety is the number one deal here.

We've seen where having the adequate safety equipment, like arc suppression and preventing that arc blowback, really cut the chances of accidents way down. Regular checks and training for the folks using these systems are crucial in ensuring safety.

3. Customization and Scalability for Industrial Needs

Every industry has its own unique industry-specific requirements. We've helped enterprises or companies who needed systems tailored just for them. We determine how enterprises or companies work, see what might be challenging or difficult, and then make a system that is adaptable and expandable as needed.

4. Energy Efficiency and Cost Reduction

Enterprises worry significant concerns about energy consumption levels they use. Our systems are built to use reduced energy consumption and generate savings on the functionality or activities side. By tweaking the arc welding or electrical discharge ignition process, we've helped enterprises or companies save a lot on energy, which is great for the environment as well.

5. Integration with Advanced Control Systems

These days, you can combine or integrate large electrical arc power systems with fancy control technology to make them work more effectively or with greater efficiency. We've seen how this kind of teamwork has helped improve performance or productivity and minimize waste or reduce inefficiency. Our know-how with integrating systems makes sure our enterprises or companies really make the most of their arc welding or electrical discharge ignition process gear.

Related articles

- Scratch Resistance Tester: A Comprehensive Guide

- Delving into the GR-F4D-Jingbang Technology Test Fixture D Probe

- Drop Impact Test Equipment Exporter: Navigating the Global Market

- Medical Power Safety Test: Ensuring Safe Practices in Healthcare

- The Necessity of Quality Electrical Appliance Testing Equipment

- Designing the Ultimate Customized Dust Simulation Chamber

- What Sets IPX6 and IPX7 Apart?

- The Why and What of Vertical Storage