Events

Revolutionizing Textile Quality: Fiber Testing Machine Insights

News 2025-04-01 9

Alright, so as the textile industry keeps getting better and better, ensuring our threads and fabrics are of high quality is very important. Now, there's this nifty fiber testing gadget for fabrics that's a major achievement for making sure the fabrics meet the required quality. We're gonna dive into five fascinating aspects about these devices and share some real-world situations that happened.

Next up, they're pretty versatile. They can test a bunch of different fibers.

Next on the list is how user-friendly these machines are.

Let's talk about hooking these machines up with something called quality management systems.

Lastly, we got to chat about the environmental angle.

Number one, it's all about how good these machines are at giving us accurate data – that's super crucial.

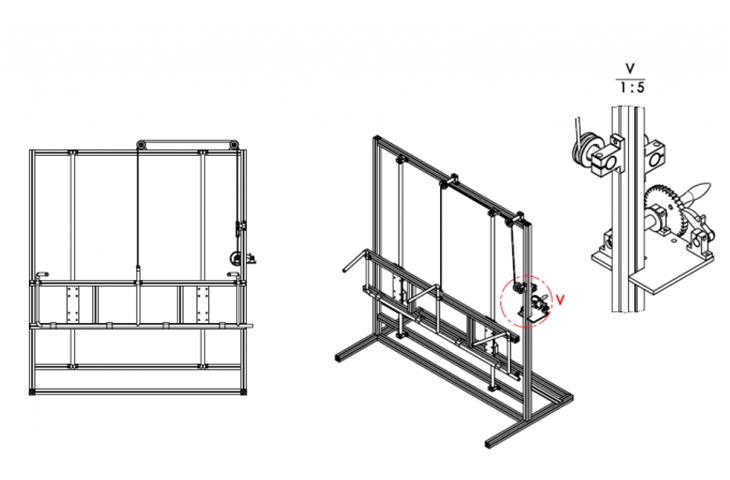

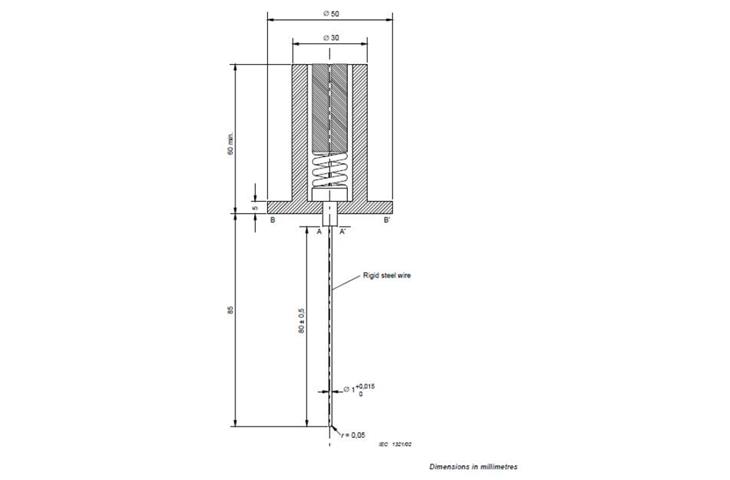

Okay, these testing gadgets for fibers? They must be extraordinarily precise and reliable. They're built to provide exceptionally detailed outcomes that are needed to maintain our products at the highest quality.

Like, researchers conducted a study and found out that if you use a good testing machine, you can reduce defects by 30%. It's not just cost-effective, but it also enjoys greater customer satisfaction.

Next up, they're pretty versatile. They can test a bunch of different fibers.

These modern fiber tester things are real all-rounders, able to deal with numerous types of fibers. From natural fibres such as cotton and wool to synthetic fibres such as nylon and polyester, these machines can test all of them. That means manufacturers can inspect their goods no matter what kind of fiber they're using, and make sure they meet the standard required by everyone.

Next on the list is how user-friendly these machines are.

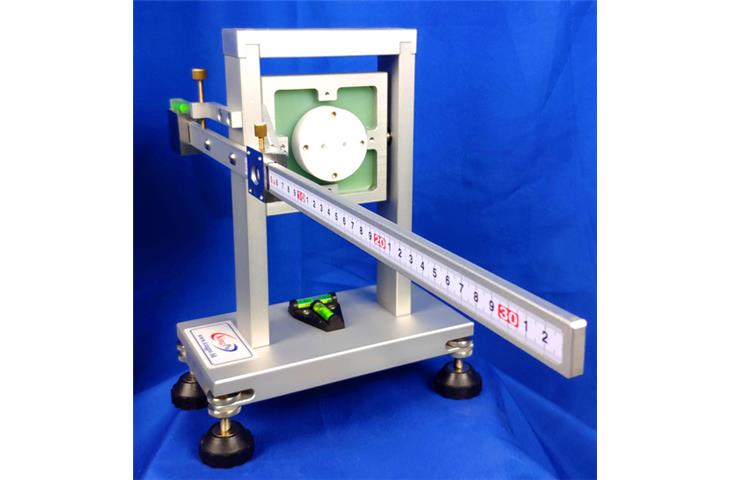

In the past, these devices were a bit of a complex task and you needed specific training to use 'em. But nowadays, the the systems possess considerably simpler methods of operation, so greater accessibility independent of to be professionals. So, this change has made it so even small businesses and upstart ventures can get ability to utilize these fancy evaluation capabilities independent of to go through thorough training.

Let's talk about hooking these machines up with something called quality management systems.

Putting these fiber tester gadgets together with product standards control software? This is significant in the business. By Automating processes, these machines make managing product standards extremely straightforward.

Some individuals at MarketsandMarkets said that this quality management system is set to grow big time from 2020 to 2025. This integration makes the quality assurance process more efficient and keeps it uniform, too.

Lastly, we got to chat about the environmental angle.

With everyone getting more eco-aware, we can't be unaware of what these textile testing devices are doing to our planet. More and more folks are looking for green gadgets that don't consume excessive energy or generate too much waste. So, if we choose machines that don't consume energy unnecessarily and implement environmentally friendly practices, the textile industry can help contribute to sustainability for all of us.

Related articles

- IPX5 vs IPX7: The Waterproof Showdown

- The Essential Role of Household Appliances Testing Equipment

- Optimal Calibration Frequency for Test Equipment

- Where Tensile Tester 0 Shines

- How to Choose the Right Constant Temperature and Humidity Oven Manufacturer

- When Lightning Surge Generators Are a Necessity

- Enhancing Precision in Healthcare: The Automated Test System for Electronic Medical Equipment

- Why ISO Injection Molders Are Key to Quality