Products

Rubber Cables Flexing Test Apparatus IEC 60227.2 Figure 1 0.33m/S

Products Description

Rubber Cables Flexing Test Apparatus IEC 60227.2 Figure 1 0.33m/S

Equipment overview:

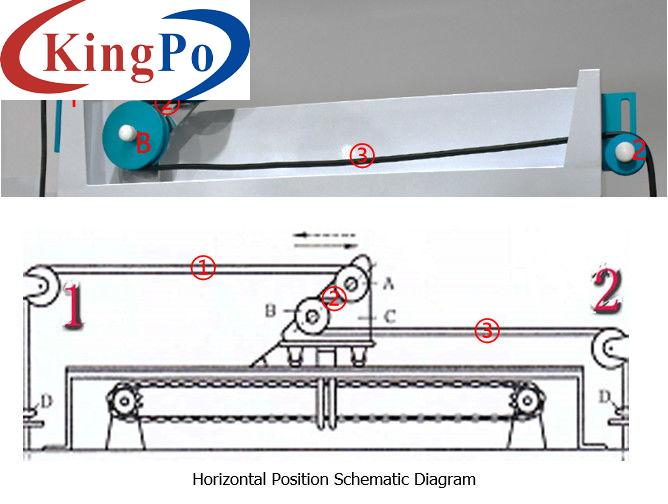

The test machine is designed and manufactured according to standard IEC 60227.2 Clause 3.1 Figure 1, IEC 60245.2 Clause 3.1 Figure 1, IEC60245-1 clause 5.6.3.1 and etc. It complies with the relevant standard requirements of rubber plastic wires’ and cables’ mechanical strength flexing test. This test does not apply to flexible cables with cores of nominal cross-sectional area greater than 4mm2 and cables having more than 18 cores laid up in more than two concentric layers.

The test apparatus can meet the standard test requirements of the domestic and international standards, can be widely used. It has precision digital meter, thus, can accurately measure the smaller or larger current voltage. The change method for pulleys is simple and convenient. The test equipment adopts to chain drive mechanism, the performance is stable and the noise is rare.

Technical Characteristics:

How to installand adjustof the pulleys?

Power Supply

3 phase 5 wires 220VAC/ 60 Hz or 380V/50Hz

Load Current

0.5~25A, adjustable

Load Voltage

Line-to-line voltage 10~400V adjustable

Testing speed

0.33m/s

Testing distance

1000±20mm

Suitable cores

2-18

Nominal cross-sectional area

0.2~4mm2

Diameter of pulleys

60, 80, 120, 160, 200mm

Test weights

2*0.5kg with hook, 2*0.5kg with hole, 6*1kg with hole, 2*6kg with hook