Products

SECC Steel Plate Battery Thermal Impact Thermal Abuse Test Chamber

Products Description

IEC 62133-1 SECC Steel Plate Battery Thermal Impact Thermal Abuse Test Chamber

Product information:

It conforms to IEC62133-1:2017 clause 7.3.5, IEC62133-2:2017 clause 7.3.4, IEC61960, IEC60086-4 clause 6.5.7, IEC 60086-1 etc.

The battery thermal impact tester, also called the battery thermal abuse test chamber, uses a hot air circulation system by simulating a battery placed in a forced-air high temperature box, raising the temperature to a set test temperature and maintaining a certain time at a certain heating rate. It can ensure even distribution of working temperature.

Parameters:

Features:

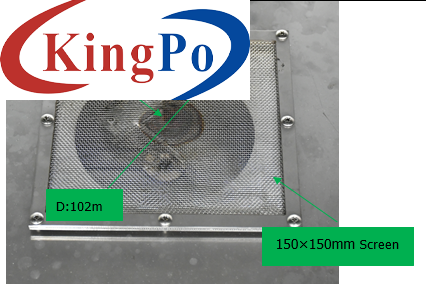

Air Supply System:

1.Forced Air Conveying circulation design. The air source generated by circulation motor driving the wheel and force the air pass through the heater to convey the hot air into the drying chamber while the used air can be inhaled to the air channel as the air source and be heated again. This way is taken to reduce the energy loss and assure the temperature in uniform distribution in the chamber. If any disturbance of door open or close, this air conveying and circulation system can recover the operational temperature value in a short time.

2. Long axis high temperature resistant motor, power 1HP60Hz

3. Blower with multi impeller turbo type, high strength, inner installed with adjustable air flow plate, make the air channel smoothly.

Temperature range

Ambient temperature~200℃ (controllable)

Control Accuracy

±0.5℃

Distribute Temp.

±2.0℃(non-load)

Temperature rising rate

5℃±2℃/minute (RT~150℃)

Control Method

PLC Touch Screen Control

Working room dimension

W600mm×D500mm×H600mm

External Dimension

W940X D780 X H1620mm

Inner Chamber Material

SUS304mirror stainless steel, clean and smooth internal chamber, easy for cleaning, with high corrosion resistance performance. All internal material with environment friendly material, inter barrel with no trace argon arc welding

External Chamber Material

SECC steel plate, powder painted (thickness1.5mm)

Bottom

Installed with universal wheel

Observation Window

Toughened glass with bursting disk.

Insulation Material

High density glass wool, well insulation, best ensure the temperature insulation. With high temperature resistant silicon seal, long time bear high temperature above 300 degrees.

Power Source

AC 220V ±10%,60HZ

Heating Power

About 3KW

Touch Screen Monitoring Picture