Products

Telcordia GR-326-CORE Optical Fiber Movable Connector Mechanical Strength Testing Machine

Products Description

Telcordia GR-326-CORE Optical Fiber Movable Connector Mechanical Strength Testing Machine

Product information:

Standard: D/T2152-2010 "Optical Movable Connectors Reliability Requirements and Test Methods" Sections 5.3.6.2, 5.3.6.3, 5.3.6.4 and 5.3.6.5

Telcordia GR-326-CORE (1999), Telcordia GR-468-CORE (2004), Telcordia GR-1209-CORE (2001), Telcordia GR-1221-CORE (1999)

Specimen and limitations: Optical fiber movable connector

Test purpose: It is suitable for detecting the degree of damage of optical fiber movable connectors after a certain number of bending, torsion, side pull and tensile stress under load, and verifying its mechanical reliability.

Test principle: It adopts PLC control and servo motor drive to perform bending test, twisting test, tensile test and tail stretching test on the optical fiber connector, and at the same time, a certain load force is applied to the sample. The test speed, angle and test times can be preset through the touch screen.

Equipment structure and features: Table-operated structure, strong versatility.

Equipment size: WDH=1100X800X1620mm, weight about 150kg

Technical parameters:

1. Bending test

2. Torsion test

3. Tensile test

4. Tail tensile test

Mechanically clamped to a special fixture, the clamping point position is adjustable

Control system

Mitsubishi PLC control, 7-inch color touch screen operation

Drive mode

Motor + precision screw guide rail forming transmission mechanism

Test station

Single station

Test items

Main technical parameters of bending test

Sample

Optical fiber cable movable connector

Sample clamping method

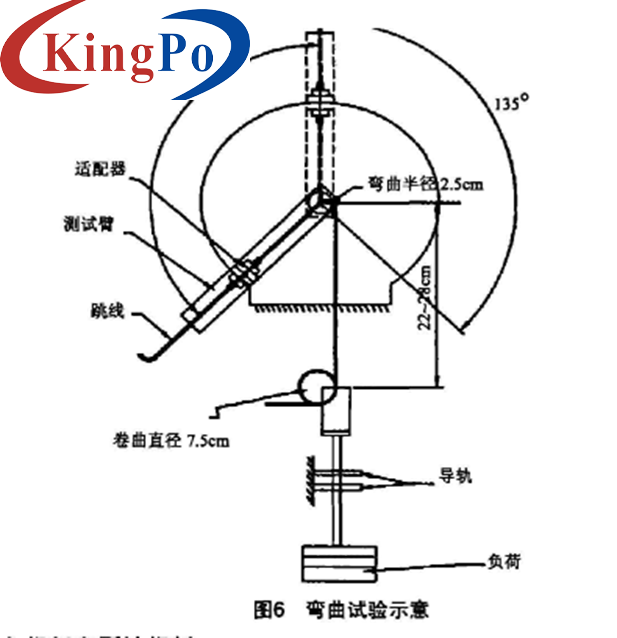

Bending angle

0-360° adjustable (can be preset to ±30°, ±45°, ±60°, ±90°)

Bending direction selection

Bending rate

0-60 times/min, touch screen preset

Bending times

0~999999 can be preset, the default is 100 times

Load weight

0.6kg, 0.9kg

Insertion and return wear and tear

External testing

Main technical parameters of torsion test

Sample

Optical cable type optical fiber movable connector, coated optical fiber type, bare optical fiber type

Sample clamping method

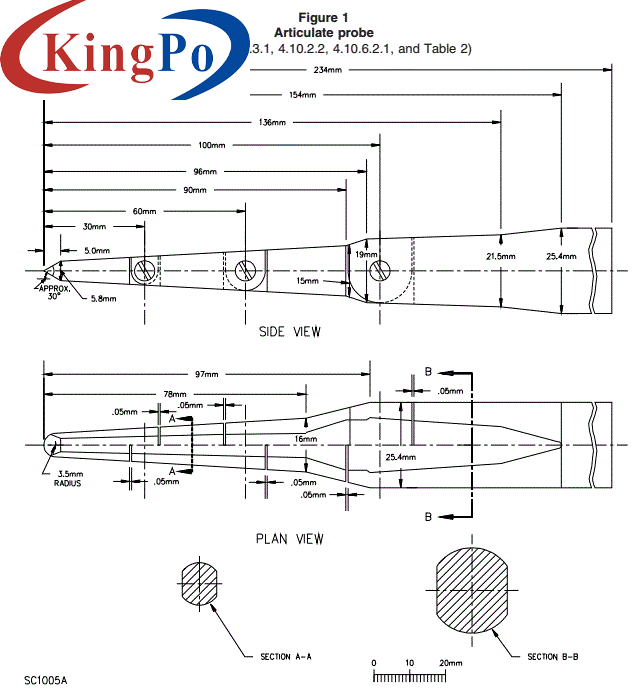

Mechanically clamp it to the special fixture according to Figure 6, the clamping point position is adjustable

Direction of rotation

Forward and reverse rotation can be selected (can be preset to rotate forward n times and then reverse n times)

Bending direction selection

Rotation rate

0-10r/min, touch screen preset

Number of rotations

0~9999.9 can be preset, the default is 9 times

Selection table for number of specimen rotation turns

Table 2 Winch rotation requirements

Tail type

Clockwise rotation (circle)

Counterclockwise rotation (circle)

Optical cable type

2.5

5

Optical fiber type

1.5

3

Load weight

0.5kg, 0.75kg, 1.35kg

Insertion and return wear and tear

External testing

Main technical parameters of tensile test

Sample

Optical fiber cable movable connector

Sample clamping method

Mechanically clamp it to the special fixture according to Figure 6, the clamping point position is adjustable

Rotational position

0° (straight pull), 90° (side pull), automatic switching

Force application method

The motor controls the lifting and lowering of the pallet to lift and release the weights to achieve the purpose of applying pulling force.

Force application time

0-9999S, touch screen setting

Load weight

1.5kg, 2.3kg, 3.4kg 4.5kg, 6.8kg, superimposed combination to achieve

Insertion and return wear and tear

External testing

Main technical parameters of tail tensile test

Sample

Optical cable type optical fiber movable connector, coated optical fiber type, bare optical fiber type

Sample clamping method

Mechanically clamp it to the special fixture according to Figure 6, the clamping point position is adjustable

Rotational position

0°, 90°, 135° automatic switching

Rotation rate

0-10r/min, touch screen preset

Direction of rotation

Swing in sequence from 0° to 90° to 135°

Load weight

0.25kg, 0.5kg, 0.7kg, 1.5kg, 2.0kg 4.5kg, 6.8kg, superimposed combination to achieve

Sample load selection table

Table 3 Load requirement

Load

0°

90°

135°

Optical cable type

0.25kg

√

√

√

0.7kg

√

√

-

1.5kg

√

√

-

2.0kg

√

√

-

Φ0.9mm Coated Fiber Type

√

√

√

√

√

-

Φ0.25mm Bare fiber type

√

√

-

√

√

-

Note: √ Indicates the test to be conducted

Insertion and return wear and tear

External testing