Products

Temp. 76±2°F Humidity 50% Energy Efficiency Test Lab Of ENERGY STAR Qualified Ceiling Fans

Products Description

Temp. 76±2°F Humidity 50% Energy Efficiency Test Lab of ENERGY STAR Qualified Ceiling Fans

Overview:

The ceiling fan energy efficiency test conforms to the standard of " Building a Testing Facility and Performing the Solid State Test Method for ENERGY STAR Qualification of Ceiling Fans ".

The test system adopts IPC computer control, and the equipment testing work is completed automatically. The test data is recorded, saved, and the air volume report and energy efficiency rating are generated automatically. The data is accurate, good repeatability, high efficiency, and convenient to be stored. The test system is driven by a servo motor to ensure that the test process runs smoothly; the wind speed is measured with an imported precision anemometer; the console is placed outside the test house, ensure that the operator will not affect the wind field.

Standards:

Can be designed according to the following standards:

► Building a Testing Facility and Performing the Solid State Test Method for ENERGY STAR Qualification of Ceiling Fans

► Other standards

Types of UUT :

ENERGY STAR Qualified Ceiling Fans

Technical Parameters:

Ceiling Fans:36″,42″,44″,48″,52″,56″,60″

Constant temperature and humidity air conditioning:

Temperature: 20-50°C±1°C, default 24.5±1°C, i.e. 76±2°F;

Humidity: (20-80) % ± 3%., The default is 50%,

Used to adjust the test room’s temperature and humidity, with the automatic throttle switch system

Mounting rail:

10ft*2 pieces

8ft*1piece

4ft*1 piece

Arranged by: Figure 3.2– Rail Measurements and Details

Test cylinders: 44″X36″, 50″X36″, 52″X36″, 56″X36″, 60″X36″, 64″X36″, 68″X36″, total 7 pieces

Selected according to: Table 3.1– Cylinder and Sensor Selection Guide

Equipment Structure:

No.:

Name

Contents

1

Test Samples

2

Test Room

heat preservation moisture-proof material: double color steel cold storage plate, total thickness 75mm, steel plate thickness 0.6mm

Inner space size L*W*H:20 ft. x 20 ft. x 11 inch

Sample lifting device: height adjustment range: 500mm, computer controlled, electric lift.

3

Test Cylinders

Test cylinder arranged according to Figure 3.8 – Air Delivery Room Set-Up with 60” Cylinder

Test cylinder mounting device: can lift to achieve facilitate installation

4

Wind Speed Measurement

Rotary swing arm: Servo motor drive,0-360°, arranged by Figure 3.8 – Air Delivery Room Set-Up with 60” Cylinder

Wind speed sensor:Arranged on the rotating swing arm starting from the center of the swing arm at a distance of 4”; set up 9 pieces; 0.15-20m/s

Sampling frequency: 1time/s

5

Rotating Speed Measurement

Photoelectric speed measurement, speed value input into the computer directly

6

Power Detection

Yokogawa WT310 Power Meter

7

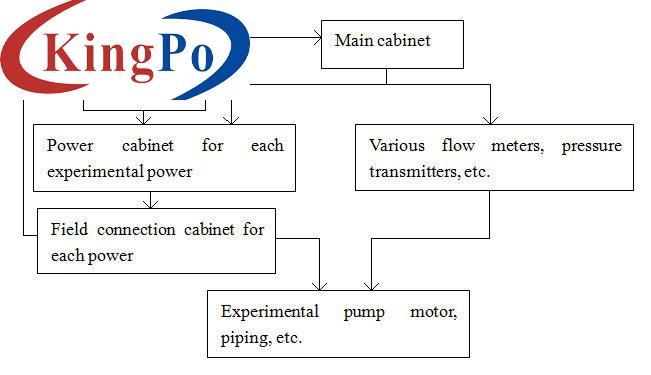

Electric control

PLC control, industrial computer operation, data acquisition, analysis, computer judgment

8

Frequency Power

Provide rated voltage and stable frequency