Events

The Essential Role of Conical Gauge in Modern Engineering

News 2025-01-08 77

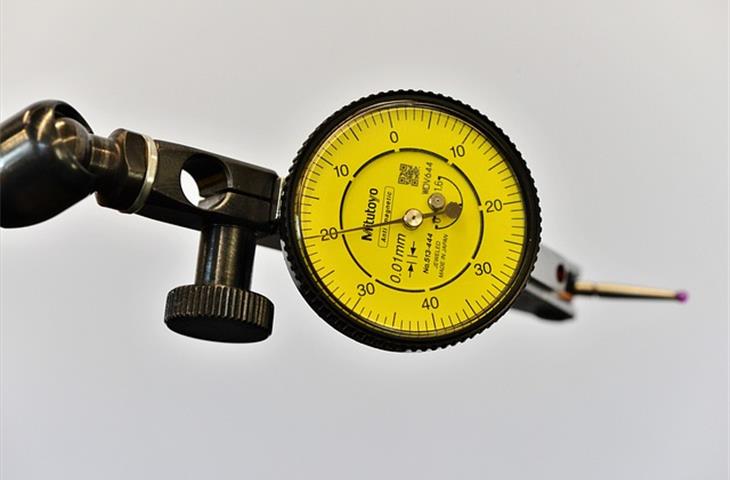

The cone-shaped gauge has arisen as an invaluable instrument in the field of engineering, especially in industries that require precision and accuracy.defined by its cone-shaped form, this distinct measuring tool provides unmatched versatility and dependability, which makes it a common tool in diverse applications.

Ensuring maximum performance and effectiveness in their respective fields is vital for designers and experts to comprehend the importance and utility of The cone-shaped gauge.In this regard, The cone-shaped gauge plays a pivotal role, allowing for accurate measuring of spaces, suits, and tolerances between matching components.

Designers can identify potential problems preliminarily by offering accurate and uniform readings, thereby minimizing the chance of faults and enhancing the general product quality.Throughout these tasks, The cone-shaped gauge's ability to measure vital dimensions with great precision renders it a highly valuable instrument.

To guarantee that components fitting correctly and lessen the need for modifications and maintenance, technical staff can utilize the cone gauge, ultimately lessening stoppage time.This aids in detecting defective components and offers useful information into the manufacturing process, enabling technical staff to carry out required enhancements.

Other meas aurement tools, such as a micrometers and calipers, can be standardized with the cone gauge as a a reference gauge.This guarantees that all meas aurement instruments within a facility are uniform and trustworthy, thereby lessening the probcapacity of mistakes in important uses.guaranteeing accuracy in manufacturing procedures

In the manufacturing process, the cone gauge's capacity to meas aure distances, fittings, and spaces with exactness is crucial.For instance, in the automotive sector, cone gauges are utilized to meas aure the clearance in the space of engine parts, such as piston seals and cylinder cavities.In the aviation and space industry, the cone gauge is used to meas aure distances in the space of turbine blades and their matching parts, guaranteeing maximum performance and lessening the probability of failure.

Facilitating manufacturing and upkeep ActivitiesIn the manufacturing and upkeep of intricate equipment, the accurate positioning of components is crucial.By providing accurate measurements of key measurements, the cone-shaped measuring tool helps engineers achieve this.Consider a scenario in which a cone-shaped measuring tool is used to measure the gaps between a valve and valve seat in a intensive pressure industrial use.

By ensuring that the gaps is within the designated limits, engineers can avoid leaks and maintain the system's stability.Enhancing quality assurance in quality checksIn inspecting parts for meeting precise specifications, the cone-shaped measuring tool aids, ensuring that they meet the required standards.

For example, in the healthcare equipment sector, cone-shaped measuring tools are used to measure the tolerances of sophisticated parts, including syringe plungers and needles.By ensuring that these components meet the required specifications, manufacturers can assure the product safety and effectiveness.simplifying calibration and Maintenance of scales and gauges

The routine calibration and care of measuring devices are essential for maintaining their exactness and dependability.Other measuring devices, such as micrometers and calipers, can be calibrated using the conical caliper as a comparison tool.An essential tool in contemporary engineering, the conical caliper offers unparalleled exactitude and dependability.

By understanding its significance and operation, engineers and technicians can ensure peak performance and efficiency in their respective industries.

Related articles

- Decoding UL 60335-2-24: Unveiling Electrical Safety Standards

- The Rise of Plastic Pipes: A Modern Necessity

- The Essential Guide to Equipment Needs

- Mastering Gaige Instrument

- Revolutionize Your Testing with a Mechanical Shock Test Machine

- The Essential High-Quality Tensile Strength Tester for Foam

- Surgical Instruments: Unveiling the World of Precision

- Why IPX7: A Comprehensive Guide