Products

Toilet Seat Mechanical Strength Test Machine IEC 60335-2-84 Mechanical Stresses Testing

Products Description

Toilet Seat Mechanical Strength Test Machine IEC 60335-2-84 Mechanical Stresses Testing

Product information:

Standard:IEC 60335-2-84 “Household and similar electrical appliances-Safety-Party 2-84: Particular requirements for toilet appliances” clause 21.103.1&21.103.2. It used to check whether the toilet seats have adequate mechanical strength and are constructed to withstand repeated mechanical stresses that may be expected to occur during normal use.

Test Contents:

1. 1250N force test:

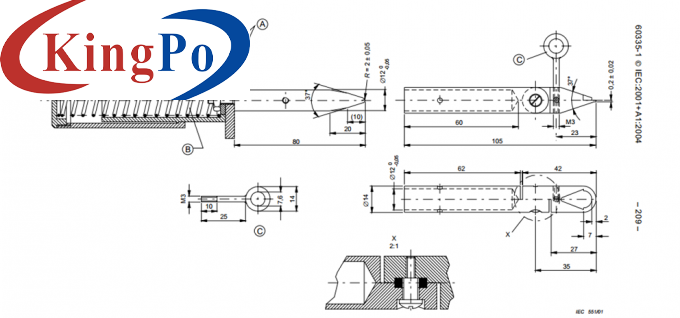

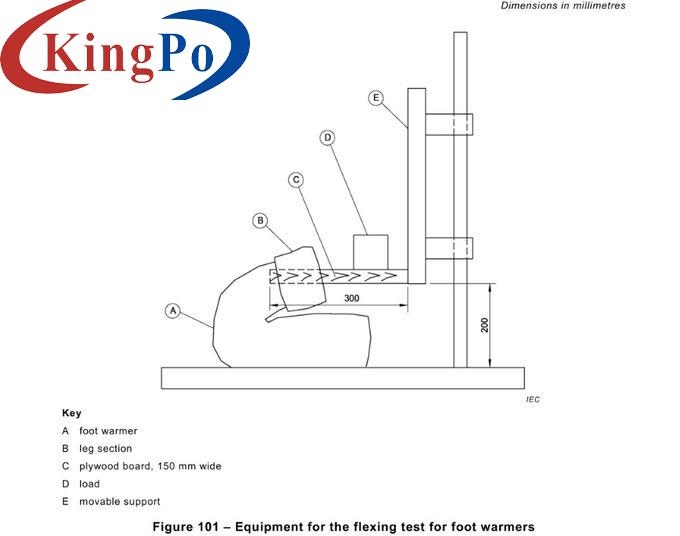

The appliance is subjected to an evenly distributed force of 1250N applied perpendicularly to the seat for 4s by a rubber disc having a thickness of 10mm, a diameter of 300 mm and a shore A hardness of 70°, with a steel disc having a thickness of 5mm and a diameter of 30mm attached on its upper surface. The test is carried out 20 000 times.

2. 890N force test:

The appliance is subjected to an evenly distributed force of 890N applied perpendicularly on each side of the seat for 1s with 0.5 s interval by a rubber disc having a thickness of 19mm, a diameter of 76 mm and a shore A hardness of 70°. The test is carried out 10 000 cycles. One cycle consists of applying the force to one side and the other.

Technical Parameters:

1. 1250N force test

2. 890N force test

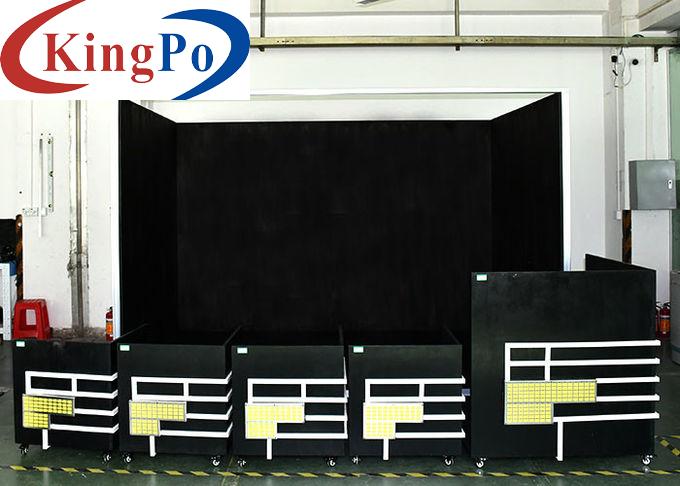

Test station

Two stations can be independently tested at the same time; (one station for 1250N force test , the other station for 890N force test)

Force applied method

Adopts the air cylinder drive method

Test contents

Force sensor range

0-2000N, accuracy class 0.5

Force adjustment method

By adjusting the air pressure

Pressure display mode

Digital pressure sensor

Equipment frame

Industrial aluminum bracket

Air cylinder for 1250N force test

Cylinder inner diameter Ø63mm, stroke 150mm

Specification of disc for 1250N force test

Diameter Ø300mm, thickness 5mm steel plate + 10mm rubber plate (shore A hardness of 70°)

Force applied time for 1250N force test

1~ 10S can be preset

Cycles of 1250N force test

1 ~ 99999 cycles can be set

Air cylinder for 890N force test

Cylinder inner diameter Ø50mm, stroke 125mm

Specification of disc for 890N force test

Diameter Ø76.2mm, thickness 19mm rubber plate, shore A hardness of 70°

Force applied time for 890N force test

0-99.9S can be preset

Cycles of 890N force test

1 ~ 99999 cycles can be set

Force applied angle

Adjustable left and right application angle

Force measurement method

Calibrate the air pressure when setting the force value through the load cell before the test, and maintain the test air pressure during the test to ensure the test force value

Control method

PLC and 7” touch screen

Power supply

Single phase 220V, 60Hz, 1KW

Machine dimensions

About 1700X700X1400mm (length, width and height)