Products

UL 2580 Electric Car Battery Pack Rotation Test Equipment For Vehicle

Products Description

UL 2580 Electric Car Battery Pack Rotation Test Equipment For Vehicle

Standards for Electric Car Battery Pack Rotation Test Equipment:

UL2580 Batteries for Use In Electric Vehicles Clause 18:

1. Rotate the battery pack 360°around X axis with rotation speed of 90°/5s, then stop and observe for a certain period of time.

2. Rotate the battery pack 360°around Y axis with rotation speed of 90°/5s, then stop and observe for a certain period of time.

3. Rotate the battery pack 360°around Z axis with rotation speed of 90°/5s, then stop and observe for a certain period of time.

4. Accept standard: Battery pack or system has no electrolyte leakage, no rupture at case, no fire nor explosion.

Gb/T31467.3-2015 Lithium-ion traction battery packs and systems for electric vehicles Part 3: Safety requirements and test methods Clause 7.4:

1. Rotate the battery pack 360°around X axis with rotation speed of 6°/s; secondly rotate it 90°,180°,270°,360°, and remain for one hour after each move. Then stop and observe for 2 hours.

2. Rotate the batter pack 360°around Y axis with rotation speed of 6°/s; secondly rotate it 90°,180°,270°,360°, and remain for one hour after each move. Then stop and observe for 2 hours.

3. Accept standard: Battery pack or system has no electrolyte leakage, no rupture at case, no fire nor explosion. And remain the connection reliable, the structure intact, the insulation resistance value not less than 100 Omega /V.

ISO12405-3:2014 Electrically propelled road vehicles — Test specification for lithium-ion traction battery packs and systems — Part 3: Safety performance requirements NEQ. And etc.

Technical parameters for Electric Car Battery Pack Rotation Test Equipment:

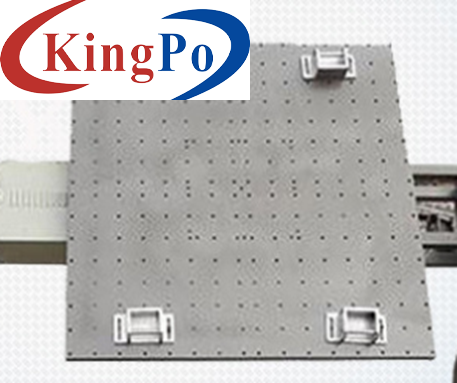

3500mm length*2500mm width*30mm thickness, material: Aluminum. It can hold samples up to 3200mm*2400mm, and the height is less than 1000mm, can compatible with small and large size specimens

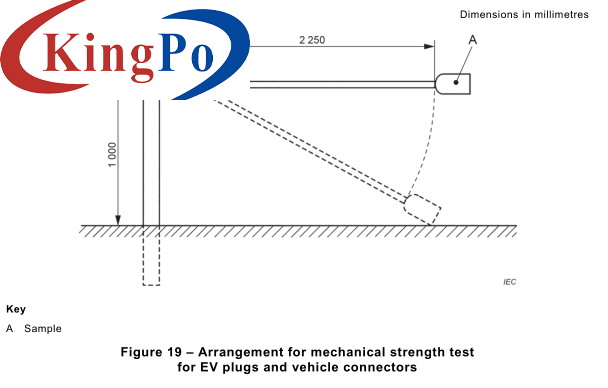

X/Y/Z axis switch automatically, as shown in the following figure, the left direction is rotate around the X-axis and the right direction is rotate around the Z-axis respectively.

The Y-axis rotation test: make the sample rotated 90° around the Z-axis first, and then rotate around the X-axis.

1°/s ~12°/s, can be preset on touch screen and computer directly

1. Fault alarm and cause, processing prompt function

2.Fault display and self-diagnosis function

3. Motor overload alarm

4. Electric leakage alarm

5. Smoke alarm

6. Power-off protection, automatic memory

7. Integrate safety relay

8. Integrate safety grating

1. Computer: Industrial all-in-one machine, with WIFI function, 1 set

2. Touch screen: WEINVIEW, 1 set

3. PLC: Mitsubishi, 1 set

4. Motor: Huichuan, 2 sets

5. Reducer: Jiacheng

6. Mechanical part: KingPo

7. Software: KingPo

8. Dedicated test room, should be provided by customers

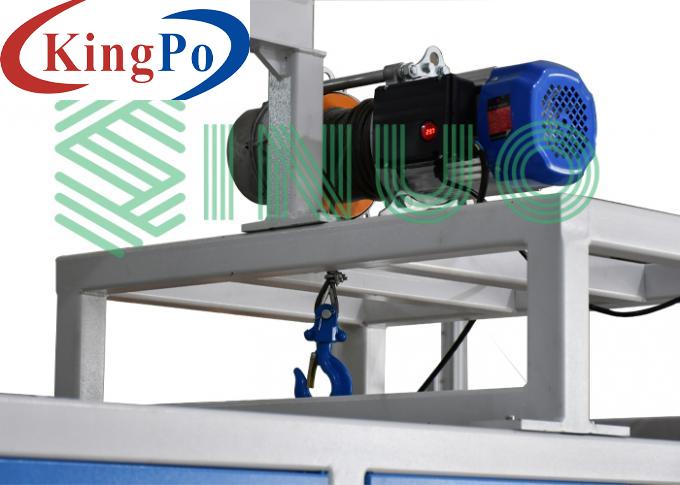

9. The battery loading mechanism, such as cantilever crane or crane, should be provided by the customer

Application for Electric Car Battery Pack Rotation Test Equipment:

The battery pack rotate test device is to simulate the battery pack or system installed on the electric vehicle. In the special circumstances of high-angle uphill, downhill, rollover, rollover, etc., to observe different conditions that battery pack or system may occur during the driving process. Present the actual use of battery packs or systems in the laboratory, find and solve problems, optimize product design, and improve product quality. The battery pack rotate test device is a special testing instrument for power battery pack or system safety test. It is the best choice for lithium battery pack manufacturers, electric vehicle manufacturers, and scientific research and testing units.

Use environment for Electric Car Battery Pack Rotation Test Equipment:

Power supply: AC380V±10%/50Hz 15KW, Ambient temperature: 5℃~+35℃

Relative humidity: ≦85%RH There should be no high concentration dust, corrosive gas and flammable and explosive atmosphere around.

Test principle for Electric Car Battery Pack Rotation Test Equipment:

Using touch screen and PLC intelligent control for close operation, computer for remote operation, and controlling the rotation mechanism to achieve 360° rotation around the X/Y/Z axis respectively. Test speed, test angle, interval time, and total test time can be set on the computer and touch screen.

Equipment structure and characteristics:

1. Adopt double reinforced column support structure, the turning action is stable and reliable

2. The large-sized perforated aluminum platform can hold 3200mm*2400mm samples, and the maximum load is 1500kg.

3. Rotation direction: X/Y/Z three axes

4. Dual system control of touch screen and computer. The touch screen can be used to adjust the test machine, and the outdoor computer can be operated during the test.

Control and operation

PLC intelligent control system, dual system operation of touch screen and remote computer

Drive

Servo motor

Platform size

Rotation direction

Rotation speed

Rotation angle

0~360°, can be preset on touch screen and computer directly

Rotation angle increment

90°, can be preset on touch screen and computer directly

Angle rotation accuracy

≦0.5°

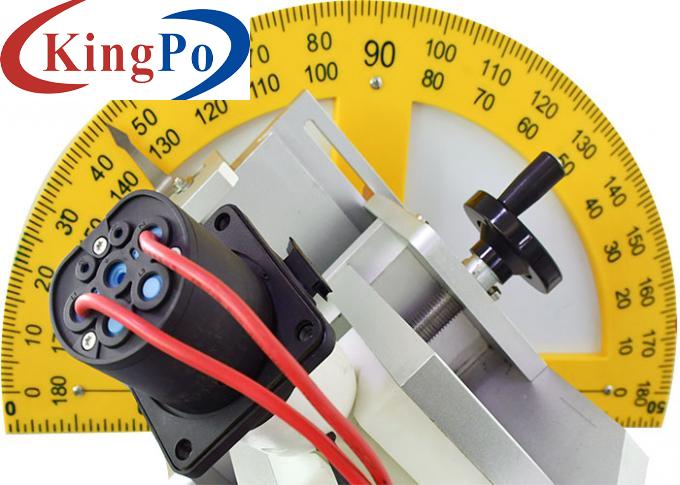

Sample clamping

Mechanical clamping

Testing process

Program automatic control

Safety protection

Monitor

2 sets of dedicated high-definition cameras monitor real-time images and record and save

Main configuration