Products

UL486A-B Table 26 Wire Damage Testing Device Screw Terminals Mechanical Stress Test

Products Description

UL486A-B Table 26 Wire Damage Testing Device Screw Terminals Mechanical Stress Test

Product Information:

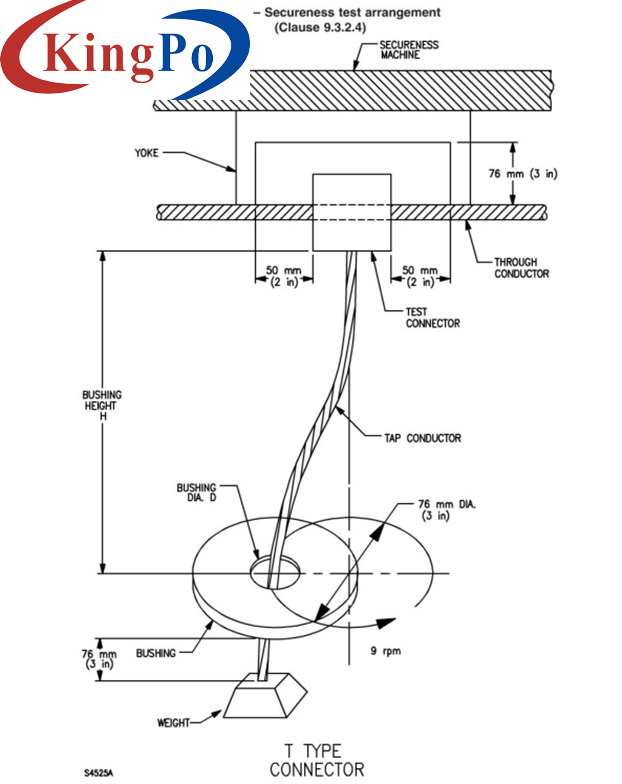

This testing device conforms to UL486A-B clause 9.3.2.1, clause 9.3.2.3, clause 9.3.2.4 and table 26 and figure 6, IEC60947-1, etc.

Specimens and restrictions: Screw terminals, threadless terminals and connectors.

Test purpose: To examine whether the screw terminals and threadless terminals can withstand the mechanical stresses that occur during normal use. It is mainly used to judge whether the design and structure of the thread clamping terminal block meet the requirements of not excessively damaging the wire when clamping the wire.

Testing principle: Using guide rail screw structure. The number of tests can be preset before use. When the set value is reached, the machine will automatically stop and sound an alarm signal.

Technical Parameters:

1. The centering locking fixture meets the requirements of terminal blocks with length, width and height of 60*70*90mm respectively. The fixture has the characteristics of quick replacement.

2. Equipped with additional mounting plate, size 300mm*250mm, which can be used interchangeably with the centering locking clamp.

3. The maximum distance between the mounting plate and the rotation center is 120mm, adjustable

5~15 rpm, can be preset on the touch screen,

(UL486A-B requires 9 rpm)

1. 0-999999, it will automatically stop when the preset number of tests is reached.

2. The test time can be switched to 0-9999min according to different standard requirements, and can be preset. It will automatically stop when the preset test time is reached.

A set of weights can achieve 0.7, 0.9, 1.4, 2.3, 3.6, 4.5, 6.8, 8.2, 11.4, 13.6, 18.2, 22.7, 25, 27.2, 34.1, 36.3, 40.9, 45.4, 49.9, 54.5, 70.4, 81.7, 93.1, 109.

Unit: Kg, weight hook is included in the total weight

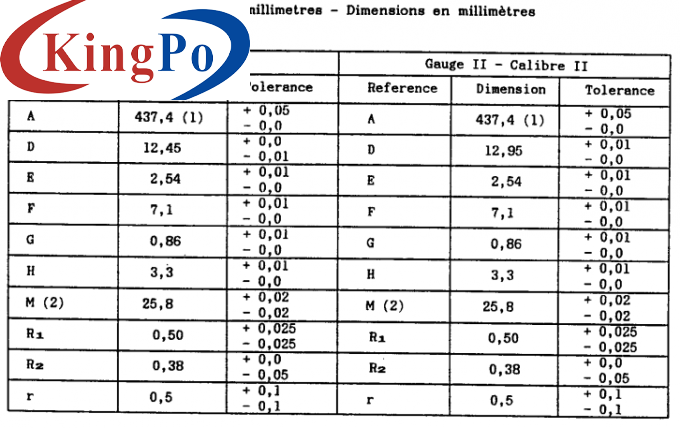

Sample specification selection

(see attached table)

The busing and mass configuring is as following table:

Control and operation

PLC control, touch screen operation

Test station

Single station

Drive

Servo drive

Fixture

Rotation speed

Rotation diameter

Adopting double-hole rotating disc, diameter ø75mm

Number of tests/time

Load weight

Height adjustment range

250~800mm, adjustable, with scale indicator

Height adjustment method

Manual adjustment

Busing diameter

UL486A-B Configuration: 6.4, 9.5, 12.7, 14.3, 15.8, 19.1, 22.2, 25.4, 28.6, 31.8, 34.9, 38.1, 44.5, 50.8, 54mm

UL486A-B Table 26

Weight lifting mechanism

Equipped with electric lifting mechanism, large-size weight tray to prevent falling