Events

What You Need to Know About Small-Bore Connector Testing

News 2025-01-08 86

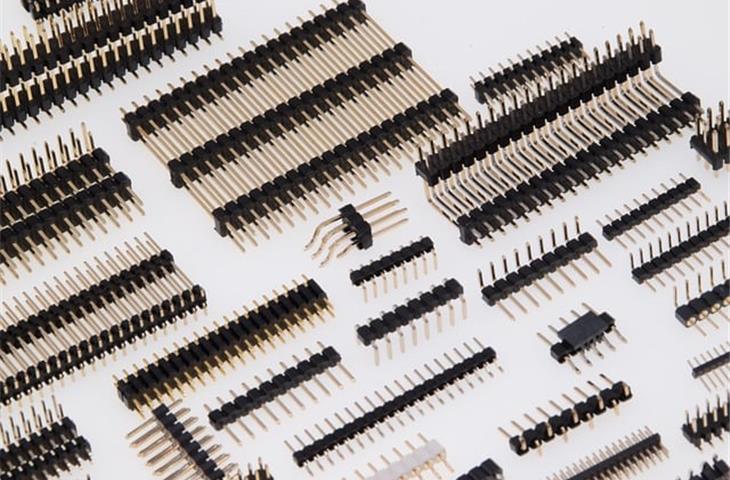

guarantee robust connections are vital functions played by narrow connectors in the world of electronics and information transfer.spacious and effective ways to connect various equipment and systems, these connectors are designed to offer.However, for the maintenance of their operation and effectiveness, regular testing is essential.

Exploring the demands and challenges involved in the process, this article investigates the intricacies of small-bore connector testing.Used widely in diverse sectors including aerospace, automotive, and telecommunications, are narrow connectors.Ideal for connecting equipment in constricted areas are their small dimension and quick information exchange capabilities.

To ensure the reliability of these connectors, thorough examination is necessary however.Maintaining the operation and effectiveness of these connectors and discussing its part, this section elaborates on the importance of small-bore connector testing.In small-bore connector testing, precision in assessment is crucial.

To guarantee the dependability of the connections' functionality, accurate determinations of parameters like electrical resistance, ability to store electric charge, and electromagnetic induction are crucial.

Related articles

- Navigating Test Equipment Depot Reviews on Reddit

- The Ultimate IPX9K Waterproof Experience: Why It Matters

- Navigating the World of Cable Equipment Suppliers

- Navigating GB9706: Standards for Medical Electrical Equipment Testing

- Why Test Equipment Depot Reviews Matter

- Navigating the Essentials of Testing Equipment Handle

- Unlocking ISO 96 PDFs: A Free Download Guide

- What to Know About Surplus Test Equipment