Events

When Packaging Testing Meets Medical Devices

News 2025-01-08 63

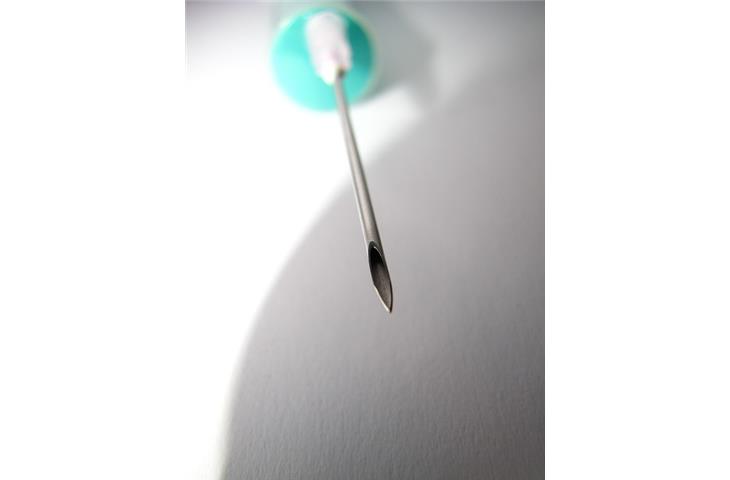

Packaging examination cannot be overstated in the fastly developing landscape of medical device production.This vital procedure ensures the secure, safe, and operational condition of medical devices upon delivery to patients.The article expounds on the complexities of medical device Packaging examination, focusing on principal criteria and each aspect's significance.

The requirements for Packaging examination in medical devices are:1. adherence with regulatory standardsIn the medical device sector, regulatory adherence is paramount. strict regulations, set by organizations including the Food and Drug Administration, International Organization for Standardization, and others, must be adhered to by Packaging examination. Meeting these standards is critical for maintaining the device's market appeal and ensuring consumer security.

Several aspects are involved in regulatory adherence, including:The choice of packaging substances, which must meet the mandatory specifications and norms.2. Protection of equipment integrityThe main aim of packaging is to protect medical devices from harm during haulage and warehousing.

This needs shock absorption: Guaranteeing the packaging can endure shocks and vibrations without damaging the device's integrity.3. Guaranteeing safety of the userClear directions, cautions, and distinguishing details offered by the packaging have a critical function in Guaranteeing safety of the user.4. Cost-effective and efficient testing methods

Maintaining an advantageous position in the medical equipment sector needs effectual packaging testing methods.Automated testing systems, for decreasing labor expenses and enhancing precision.To conclude, medical equipment packaging testing is essential, securing consumer safety, compliance with regulations, and product reliability.

Related articles

- When PV Module Test Equipment: Essential Needs and Innovations

- Luer Lock ISO Standard: Essential Demands and Applications

- What Are the Best Testing Equipment Calibration Companies?

- Falling Dart Impact Tester Quotes - Discounts Galore!

- When Norma Test E Meets Efficiency

- The Versatile World of Blister Packs: Who Needs Them?

- The Essential Guide to EMC Test Equipment Where

- Essentials of Light Testing Equipment: What You Need to Know