Events

When Plug Bending Tester Meets Precision

News 2025-03-19 69

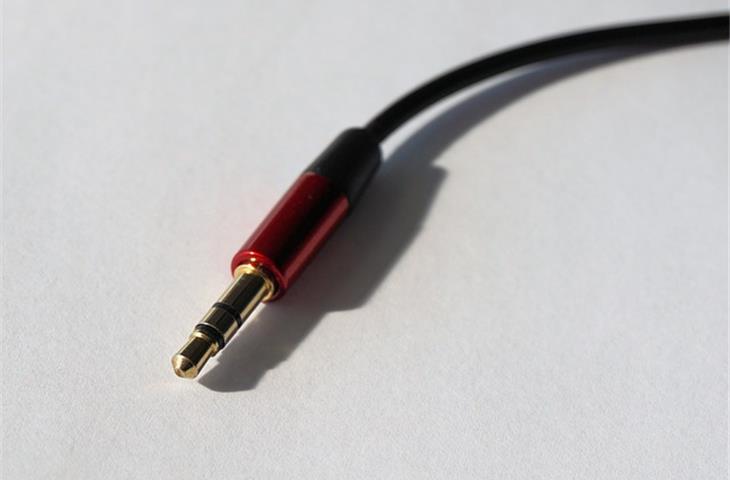

The bending tester has emerged as a crucial tool in the realm of metalworking and material assessment, which is used for assessing the bendcapacity and integrity of various materials.The device, also known as a bend fatigue tester or a plug bending fatigue tester, is designed to simulate practical bending scenarios.

By doing so, it ensures that designers and producers can produce items that meet stringent standards of quality.In this article, we will delve into the essential demands of a bending tester and explore its pivotal role in the metalworking industry.The primary demand for a bending tester is its capacity to provide accurate and exact outcomes.

The bending angle, force, and deformation of the testing material must be measured by the device with maximum precision.For designers to make informed decisions about material choice, design changes, and itemion methods, this precision is crucial.A bending tester should be adaptable enough to accommodate various types of materials, such as ferrous materials, polymer materials, and composite materials.

Furthermore, it should also be suitable for various test samples, including circular, quadrilateral, or rectangular rods.This adaptability permits a variety of uses in numerous sectors.For users to effortlessly navigate the features of the plug bending tester and configurations, an intuitive user interface is crucial.

The machine must have clear, straightforward controls and offer immediate feedback to the user while performing testing.In doing so, it not only streamlines the testing process but also reduces the likelihood of operator errors.Considering the stringent requirements of bending experiments, a plug bending tester should be built with sturdy and long-lasting materials.

The machine must have the capability to endure the forces and strains applied during testing without suffering considerable wear and tear.Bending plug testers play a crucial role in the metal fabrication industry by satisfying the requirements of great accuracy and precision, flexibility and compatibility, intuitiveness, and sturdy and long-lasting construction.

Related articles

- ISO 80369-7 Luer: A Comprehensive Overview

- Why Keep an Electrical Test Equipment List

- Where to Find the Best Medical Equipment

- The Essential Guide to Temperature Humidity Vibration Test Chambers

- What BS546 Standards Reveal

- Ultrasonic Testing Equipment Used: A Comprehensive Guide

- RPM Test Equipment: Why It's Essential for Precision

- Decoding the Mystery of IK 62262