Events

Why Test Equipment Solutions Are Essential in Modern Engineering

News 2025-01-08 437

The importance of dependable test equipment options, which is critical in the frenetic realm of engineering, cannot be overstated.dependable test equipment options act as the foundation of every prosperous venture and ensure that products meet stringent quality metrics and conform to legislative demands.

This article explores the importance of testing hardware solutions and tackles four main requirements that engineers encounter when choosing the suitable instruments for their projects.With an understanding of these demands, engineers are better equipped to make well-informed choices, which will ultimately lead to victorious results.

The primary demand in test equipment solutions revolves around the need for exactness and fineness in quantification.Test equipment is relied upon by engineers to gather information that is as close to the actual worth as possible.This is vital in guaranteeing that items are secure, reliable, and meet trade metrics.

The necessity for precise measurements is evident across diverse domains, including astronautics, motor vehicle, and the medical equipment industries.Amidst the diverse spectrum of engineering today, there is an increasing requirement for testing equipment solutions that provide flexibility and interoperability across multiple platforms and technologies.

Engineers require tools that can be effortlessly integrated into their existing setups, enabling uninterrupted examination and interpretation.This necessity is propelled by the imperative to keep pace with rapid tech development and the escalating difficulty of engineering endeavors.dependability and sturdiness represent another pivotal demand in testing equipment solutions.

Engineers depend on their test equipment to maintain stable operation over time, even in hostile environments.This is particularly significant in industries like petrochemical, where equipment must endure severe temperatures, stress, and shaking.A reliable and durable test equipment solution ensures for engineers can rely on their outcomes and prevent expensive downtime.

With technology is becoming more intricate, engineers require testing gear options with easy-to-use interfaces and thorough assistance.The requirement for intuitive programs, easy-to-understand documentation, and easily accessible technical assistance is motivated by the goal of reducing training duration and improving efficiency.

A excellently designed testing equipment can help engineers in concentrating on their main activities without being overwhelmed by difficult interfaces or the lacking assistance.Ensuring exactness and meticulousness in measurement is crucial for engineers to maintain the dependability and excellence of their outputs.High-accuracy measurement testing gear options are essential in a variety of technical applications, like aviation, vehicle industry, and healthcare equipment.

Precise measurements are fundamental in aviation engineering to guarantee the security and operation of airplanes.ultra-precision testing gear assists engineers in observing critical factors like height, velocity and deceleration, empowering so they can refine developments and conform to strict industry norms.

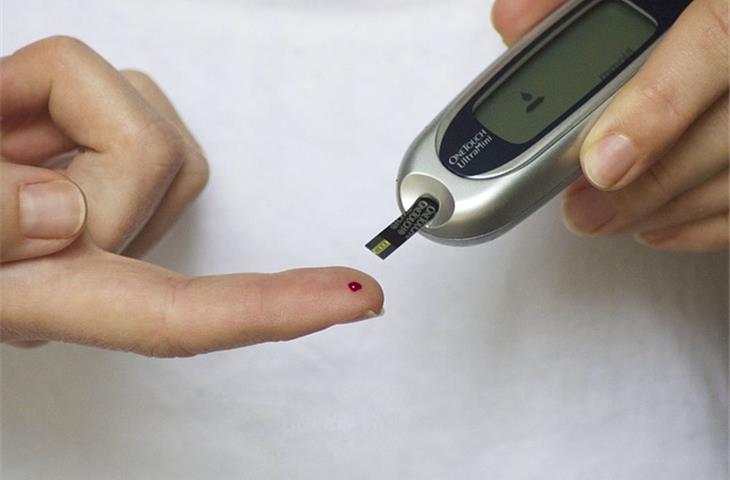

The automotive sector depends on exact measurements to nurture and test vehicles that meet safety and performance requirements.high-precision testing equipment solutions are utilized to measure engine performance, fuel economy, and exhaust atmospheric emissions, among other metrics.In the medical domain, accurate measurements are essential for ensuring the safety and effectiveness of healthcare equipment.

High-precision testing solutions are applied to measure key signs like systolic and diastolic pressure, pulse rate, and spO2 levels level, thereby ensuring that patients receive the highest quality care.In in response to the requirement for accuracy and precision, testing equipment producers are consistently enhancing their products.

This encompasses creating new sensors, calibration techniques, and computational methods designed to produce more precise and dependable readings.With the engineering environment becoming more varied, there is an escalating demand for flexible and compatible testing equipment solutions.building block testing solutions enable engineers to customize their configurations in line with their specific requirements.

This can enable expense savings and increase productivity by purchasing only the necessary parts.Testing gear equipped with standard connections such as Universal Serial Bus, Ethernet nepairrk, and serial connectivity can be easily connectd into a various systems and gear.Testing gear solutions that offer thorough program facilitateance, such as device drivers, function libraries, and programming facilitates, can facilitate technicians in conserve work timeframes and energy during the incorporation and application of the gear.

dependability and sturdiness are fundamental for Testing gear solutions, particularly in inparticulate matterries where gear should withstand challenging circumstances.Testing gear with a robust build, such as metallic casing and impact-resistant parts, is capable of withstanding harsh circumstances and mechanical force.

Testing gear designed to protect against particulate matter, humidity, and heat resistance variations can ensure reliable operation aacross diverse circumstances.Testing gear solutions with a long-lasting life span can facilitate technicians in expense reduction measures and circumventing the requirement for repeated replacement cost cycles.A intuitive applicationr connection and extensive help are essential for technicians to application Testing gear solutions efficiently.

testing devices equipped with user-friendly software can ease technicians in quick learning and using the machinery, thereby reducing training duration and improving efficiency.Clear and detailed documentation, such as user guides and guides, can help technicians in solving problems and understanding the functionalities of their testing devices.

availability of customer support, including telephone, e-mail, and real-time chat, can enable technicians to promptly solve any problems that may arise while using their testing devices.In summary, testing devices alternatives play a critical role in modern engineering.By satisfying the demands for precision, flexibility, dependability, and user-friendliness, technicians can choose the suitable equipment for their initiatives and ensure the effectiveness and excellence of their outcomes.

As innovation keeps developing, the importance of these criteria will increase, requiring that technicians stay updated and flexible to the changing landscape of testing devices alternatives.

Related articles

- What is Test Finger-Model?

- AC Load Box and DC Load Box Supply: Essential Insights and Demands

- The Six-Axis Robot Revolution: Unveiling the Future of Automation

- Comprehensive Guide to Toy Safety Testing Equipment

- Unlocking Potential: Where Industrial Shaker Tables Excel

- IPX3 Waterproof Rating: Navigating the Water-Resistant World

- Why IPX8 Waterproof Rating Matters

- How to Choose the Right Tensile Strength of Foam Tester Suppliers