Automatic IEC Test Equipment Power Cord Flexing Test Apparatus of Adjustable Bend Angle

Automatic IEC Test Equipment Power Cord Flexing Test Apparatus of Adjustable Bend Angle

- Model:

Automatic IEC Test Equipment Power Cord Flexing Test Apparatus of Adjustable Bend Angle

Automatic IEC Test Equipment Power Cord Flexing Test Apparatus of Adjustable Bend Angle

Product information:

This test apparatus checks the protection of the supply cord where it enters the appliance. It conforms to the standard requirement of IEC60335-1 clause 25.14. Appliances provided with a supply cord that are moved while in operation shall be constructed so that the supply cord is adequately protected against excessive flexing where it enters the appliance. This does not apply for appliances with automatic cord reels.

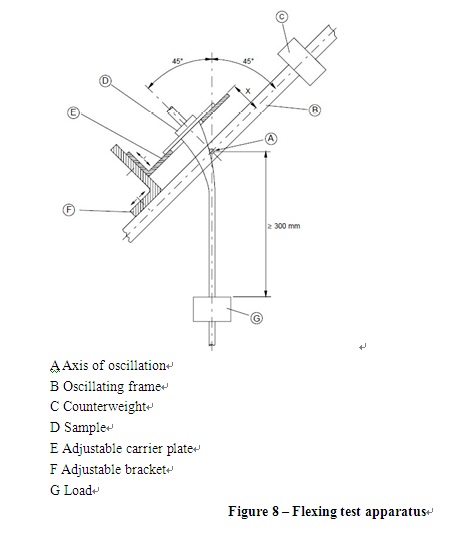

The appliance includes the inlet opening is fixed to the oscillating member so that, when the supply cord is at the middle of its travel, the axis of the cord where it enters the cord guard or inlet is vertical and passes through the axis of oscillation. The major axis of the section of flat cords shall be parallel to the axis of oscillation.

The cord is loaded so that the force applied is

– 10 N, for cords having a nominal cross-sectional area exceeding 0,75 mm2;

– 5 N, for other cords.

The distance X, as shown in figure 8, between the axis of oscillation and the point where the cord or cord guard enters the appliance, is adjusted so that when the oscillating member moves over its full range, the cord and load make the minimum lateral movement.

The oscillating member is moved through an angle of 90° (45° on either side of the vertical), the number of flexings for type Z attachments being 20 000 and for other attachments 10 000. The rate of flexing is 60 per minute.

NOTE: A flexing is one movement of 90°.

The cord and its associated parts are turned through an angle of 90° after half the number of flexings, unless a flat cord is fitted.

During the test, the conductors are supplied at rated voltage and loaded with the rated current of the appliance.

Technical parameters:

| Power Supply | AC220V 50HZ |

| Angle of bending | 45°,60°,90°or 120°,180°adjustable |

| Bending rate | 8~60rpm (frequency control) |

| Test Station | 1 station (3 working stations and 6 working stations can be customized) |

| Maximum output voltage | 240V |

| Maximum output power | 3KW |

| Maximum current output | 12A |

| Maximum load bearing of samples | 30kg |

| The load weight | 5N,10N*1 |

| Counter | 0~999999 6 digit display,preset |

| Remark | It is equipped with sample clamp or it is customized according to the sample |

Guangzhou KingPo Equipment Co., Ltd (hereinafter referred to as KingPo) is located in Guangzhou, China, formerly known as KingPo Electromechanical Co., Ltd, since 2003, engaged in developing and providing test equipment and detection system for electronic & electrical products, house appliances and other products. KingPo is professionally dedicated in providing laboratory testing equipment and production line testing system, we are now the high-tech enterprises with technical superiority and R & D capabilities in test instruments industry.

KingPo products are designed and manufactured as per the requirements of GB, IEC, EN, UL, VDE, BS, AS, ISO standards and etc. Our main products are: switch, plug, socket and coupler test equipment; mechanical strength impact test equipment; material fire hazard test equipment, enclosure protection test probes; waterproof and dustproof environmental test equipment; household appliances safety test equipment; wire and cable test equipment; luminaires test equipment; electric tools test equipment; information technology and audio & video test equipment. Our products are widely used in domestic and worldwide measurement & certification institutions, inspecting mechanism, laboratories, export & import inspection and quarantine bureau, various production companies and etc. Our customer includes Bureau Veritas, CSA, ITS, UL, TUV Rheinland, TUV SUD, SGS and etc.

IEC Test Equipment

IEC Test Equipment

IEC Test Equipment