Touch - Screen Flammability Test Chamber / Tracking Test Equipment 0.5 M³ Stainless Steel Plate

Touch - Screen Flammability Test Chamber / Tracking Test Equipment 0.5 M³ Stainless Steel Plate

- Model:

Touch - Screen Flammability Test Chamber / Tracking Test Equipment 0.5 M³ Stainless Steel Plate

PLC Control Tracking Test Equipment 0.5 M³ Stainless Steel Plate IEC60695 Flammability Testing Equipment

Product Introduction

The test machine is designed and manufactured according to the requirements of the relevant standards, such as IEC 60112, IEC60695 and etc. It is used for determination of the relative resistance to tracking performance that solid electrical insulating material under the action of an electric field, when the surface exposed to water containing impurities.

If electrical products affected by moisture and impurities environmental, leakage may be caused on the insulation between different polarity live parts or live parts and grounded metal, the generated arc will cause short circuit or electrical erosion due to discharge, even cause fire. The tracking test is a destructive test to insulating material simulating the above situation, to measure and assess the relative resistance to tracking when the insulator is in the effect of electric and impurities in water-containing.

This equipment adopts advanced PLC control system, touch-screen humanized button operating device, high quality materials and professional technology, which make itself has excellent quality, stable and durable performance and beautiful appearance. In addition, automatic drip timing device, accurate electrode pressure sensor display, simple operation and high accuracy improve the efficiency of the test and make our equipment takes a leading position in similar products.

Technical Parameters

| Timing device | 9999X0.1S Resolution | Drip interval | Adjustable | ||

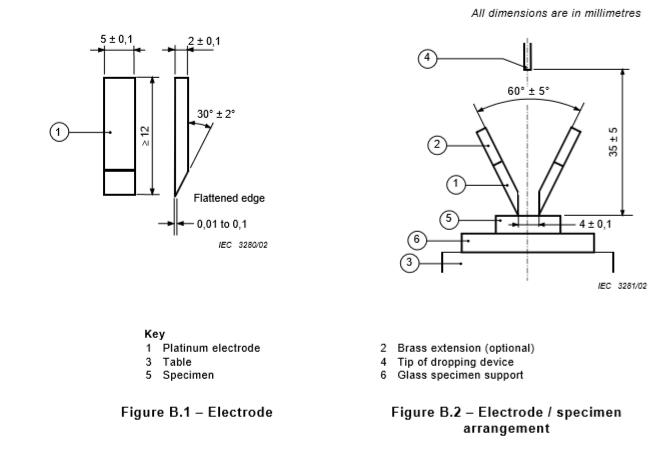

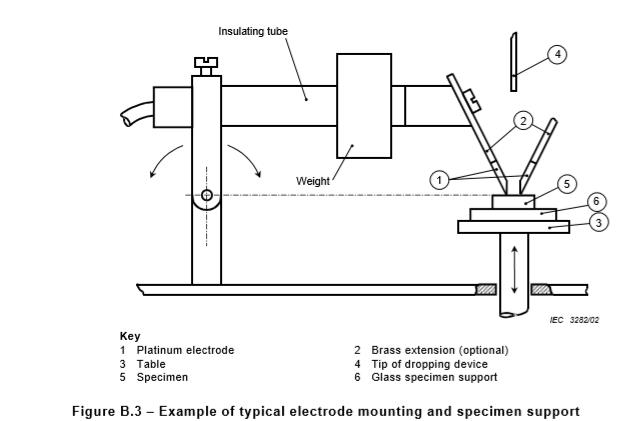

| Electrode material | Platinum | The height of the drip | 30~40mm | ||

| Electrode specifications | 5mm*2mm | Drip delay | 0.2S (solenoid valve open time) | ||

| Electrode spacing | 4±0.1mm | Drip size | 45 ~ 50 drops / cm3 | ||

| Electrode pressure | 1±0.05 N | Delay electric circuit | 2 ± 0.1S (at 0.5A) | ||

| Electrode angle | 60° | Test voltage range | 0~600V Accuracy:1.5% | ||

| Short circuit voltage drop | 8% MAX | Electrical parameters | 1.5KW/220VAC/50Hz | ||

| Short-circuit current | 1±0.1A Accuracy: 1% | Working volume | > 0.5 M³ | ||

| Environmental requirements | 0 ~ 40 ℃ / ≤ 80% relative humidity | ||||

| Standards | IEC60112, UL746A, IEC60695, ASTMD3638. | ||||

Normal Test

1. Install the electrode and sample properly, and well adjust the wind speed of exhaust.

2. Set the following parameters:

A.【Dripping Interval Time Setting】Suggested setting value(25S), it is adjustable according actual condition.

B.【Dripping Time Setting】Suggested setting value(5S), it is adjustable according actual condition.

C.【Quantity Setting 】Suggested setting value(50 drops or 100 drops ), it should be set according standard requirements.

D.【Completion Delay Time Setting】Suggested setting value(25S ), it should be set according standard requirements.

E.【Over-current Setting 】Default setting value(0.5A)

F.【Over-current Delay Time Setting】Default setting value(2S)

3. Close the observation window so that the door switch is closed

4. Press the [Start] button to start the test

A. If the current <0.5A, after the display value of 【Quantity Display 】 reaches the set value of 【Quantity Setting 】, the whole test will be completion after 25 seconds delay.

B. If the current ≥0.5A, the test will be stopped after 2 seconds delays, the system will alarm and 【Over-current Alarm 】flashes, press [Reset] button to dismal the alarm.

5. Record the relevant test parameters required.

6. After the test is completed, the exhaust fan starts automatically (it needs to be closed manually).

7. Press the [Reset] button to clear the displaying values.

7. Rotate the [Voltage Regulation], [Current Regulation] and [Current Minitrim] to the lowest position. Turn off the exhaust fan.

8. Clean and dry the glass specimen support and prepare for the next test.

Attention

The input power of this machine: 1.5KW, 220V, 50Hz, a well-grounded power supply should be connected with this machine.

Do not open the observation window during the test to prevent electric shock

After the test is completed, the exhaust fan should be opened and the test chamber should be cleaned up

When the liquid is added, turn off the fan to prevent the solution from splashing.

Fan speed is adjustable, please adjust the wind speed according to different standards.

The container is carefully placed and tilted to prevent corrosion or electrical failure.

Clean the dripping system regularly and keep the dripping line smooth.

Platinum electrode is expensive and vulnerable, please pay attention.

Electrode should be re-grinded, re-measured if it is corroded (electrodes are the wearing parts which are not covered by the warranty).

Flammability Testing Equipment

Flammability Testing Equipment

Flammability Testing Equipment